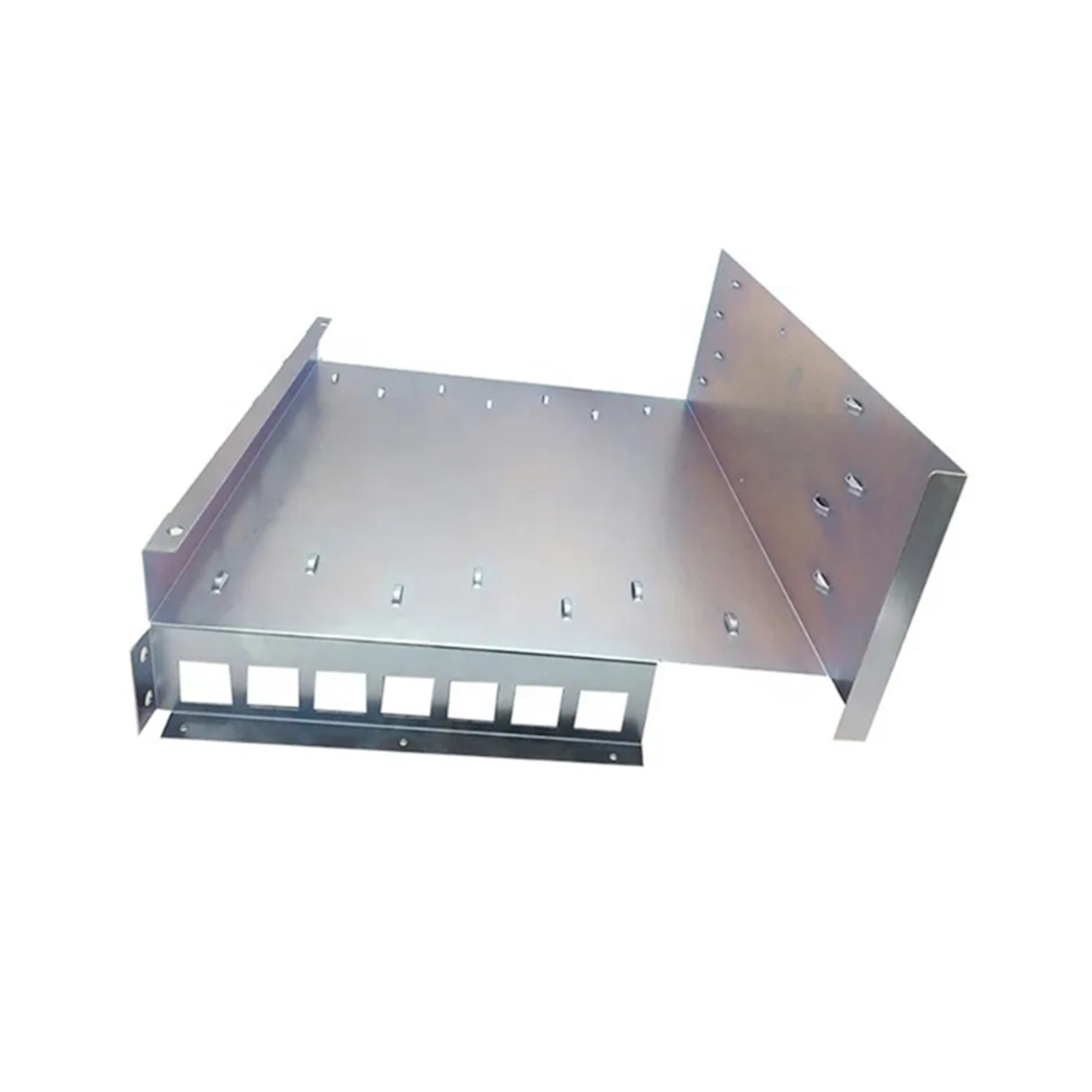

Wholesale Bending Bracket for Hoistway from Trusted Manufacturers

As a professional in the construction and machinery sector, I understand the critical role that a high-quality bending bracket for hoistway plays in ensuring safety and efficiency. My experience has shown that sourcing the right equipment can significantly enhance your project outcomes. Our bending brackets are designed with durability in mind, catering specifically for wholesale needs. I’ve partnered with leading manufacturers dedicated to delivering top-tier products that comply with industry standards. Whether you’re managing a significant renovation or a new construction project, these brackets offer reliable support that you can trust. By choosing our bending brackets, you’re not only investing in superior quality but also ensuring that your hoistway operations run smoothly. Reach out today to explore options that best suit your project needs, and let’s elevate your hoistway solutions together!

Bending bracket for hoistway Dominates Leads the Global Market

In the competitive world of construction and elevator systems, the bending bracket for hoistways has emerged as a crucial component, playing a vital role in ensuring safety and efficiency. This innovative solution allows for the seamless support and alignment of hoisting equipment, enabling elevators to operate smoothly. As the demand for advanced elevator technology continues to rise globally, the bending bracket has established itself as a key player in enhancing operational performance while meeting rigorous safety standards. Manufacturers specializing in metal products have successfully developed bending brackets that not only fulfill functional requirements but are also engineered for durability and longevity. The use of high-quality materials and precision engineering techniques ensures these brackets withstand the rigors of heavy use in demanding environments. Furthermore, the versatility in design allows for compatibility with various hoisting systems, making them highly attractive to procurement officers around the world looking for reliable and efficient solutions. As global markets continue to expand, the opportunity for sourcing robust bending brackets has never been greater. Buyers can expect to see continued innovation in this sector, driven by the need for improved technologies and sustainability practices. With a focus on quality, efficiency, and reliability, the right bending bracket is not just a component; it is an investment in the future of elevator systems. Engage with suppliers who are committed to providing top-notch products tailored to meet your specific needs, and take the first step towards enhancing your hoistway applications.

Bending Bracket for Hoistway Dominates Leads the Global Market

| Dimension | Material | Load Capacity (kg) | Application | Market Share (%) |

|---|---|---|---|---|

| 100x100x5 mm | Steel | 500 | Industrial Lifts | 25 |

| 150x150x6 mm | Aluminum | 400 | Residential Lifts | 20 |

| 200x200x8 mm | Stainless Steel | 800 | Freight Lifts | 30 |

| 120x120x5 mm | Carbon Steel | 350 | Service Lifts | 15 |

| 180x180x7 mm | Mild Steel | 600 | Dumbwaiter Lifts | 10 |

Related Products