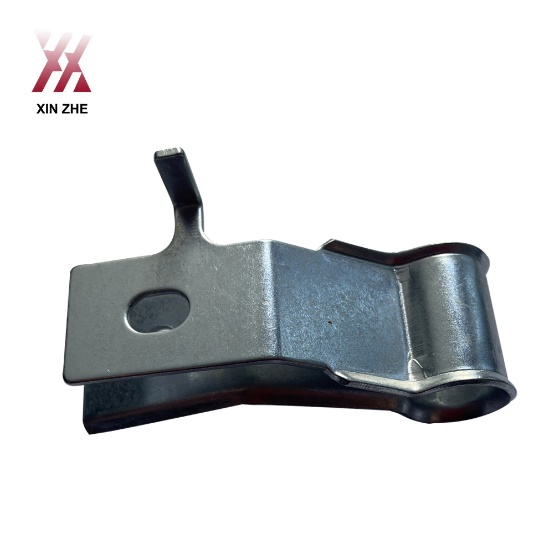

China wholesale Electrical Stamping Parts Bottom Plate Suppliers – Non-standard metal bending parts – Xinzhe

China wholesale Electrical Stamping Parts Bottom Plate Suppliers – Non-standard metal bending parts – Xinzhe Detail:

Description

Description

Analysis of typical bending stamping parts quality issues

The use of bending stamped components is extremely widespread, and the quality level has also increased. The size and appearance of the resulting stamped pieces will be significantly impacted by the bending process. To meet product quality standards and lower production costs, manufacturers of stamping parts should prevent and suggest workable solutions to common quality issues with bending and stamped parts.(Custom metal clips

/ Custom assemblies/ Custom Metal Stands)

1. Breakage

Burrs or tiny fissures frequently develop on the edge of the material after shearing or pounding. It is simple to produce stress concentration and fracture when anything bends. The cracking position occurs in the shear zone of the stamped component and is caused by the shear (surface with burrs) shearing outward and the kneading pressure belt.( Bushings/torque limiters/ Store Fixtures)

After shearing or punching, the stamped components should ensure that the shearing surface is inward while bending so that they are in a condition of compression and have a superior forming effect. The stamping components are deburred prior to bending, and the bending portion can be manually ground at the bending location after bending using a grinding wheel.( Custom Metal Brackets in Carbon/ Custom OEM Component Fabricator)

2. Rebound: The plastic and elastic deformation of the metal material are synchronized during the bending process. When bending stops, springback happens as a result of the elastic deformation recovering. Controlling the springback phenomenon is necessary because it has a direct impact on the dimensional correctness of stamped items.( Custom Metal Enclosures/ laser cutting)

Method for Angle Compensation. The length of stress speeds up correction. After the bending is complete, the contact time between the upper mold, the stamping component, and the lower groove of the bending machine is extended by pressurizing and correcting, increasing the plastic deformation of the corner of the lower groove, so that the springback of the fibers in the tension and compression zone can cancel out and thereby reduce the springback. bomb.( welding/ bending/ tools)

3. Raised: The circumstance is rather unique for the bending of medium and thick plates. The fibrous tissue in the vicinity of the bending line will lengthen during the bending process, causing bulges to form at the corners of the bend. The size of the bulges at the rounded corners grows with plate thickness, as can be seen by looking at the stamping parts created in the workshop. The rounded corner protrusions will compromise the dimensional accuracy of welding or assembly for some stamping parts with high quality standards, thus technical measures must be made to eliminate them.( hardware/ wire forming/ Shields)

Product detail pictures:

Related Product Guide:

Dependable good quality and very good credit score standing are our principles, which will help us at a top-ranking position. Adhering towards the tenet of quality initial, shopper supreme for China wholesale Electrical Stamping Parts Bottom Plate Suppliers – Non-standard metal bending parts – Xinzhe , The product will supply to all over the world, such as: Costa rica, Mexico, Armenia, Now we are sincerely consider to grant brand agent in different areas and our agents' maximum margin of profit is the most important thing we care about. Welcome all of the friends and customers to join us. We are ready to share win-win corporation.

It's really lucky to find such a professional and responsible manufacturer, the product quality is good and delivery is timely, very nice.