Wholesale Deep Draw Stamping Manufacturers: Quality & Precision Solutions

When it comes to deep draw stamping, I've found that quality and precision are key factors for manufacturers seeking reliable solutions. Our wholesale offerings are designed to meet diverse project requirements, ensuring you get the best value. Whether you need complex shapes or high-volume production, our deep draw stamping techniques deliver outstanding results every time. I've worked closely with various manufacturers, and their need for efficiency and cost-effectiveness has shaped our product line. We specialize in customizing solutions to fit unique specifications, allowing you to streamline your operations. Our commitment to excellence and attention to detail means that you can trust us to meet your demands. With competitive pricing and a proven track record, partnering with us not only enhances the quality of your products but also boosts your bottom line. Let's collaborate to create impeccable solutions that elevate your manufacturing capabilities.

deep draw stamping Manufacturer Service

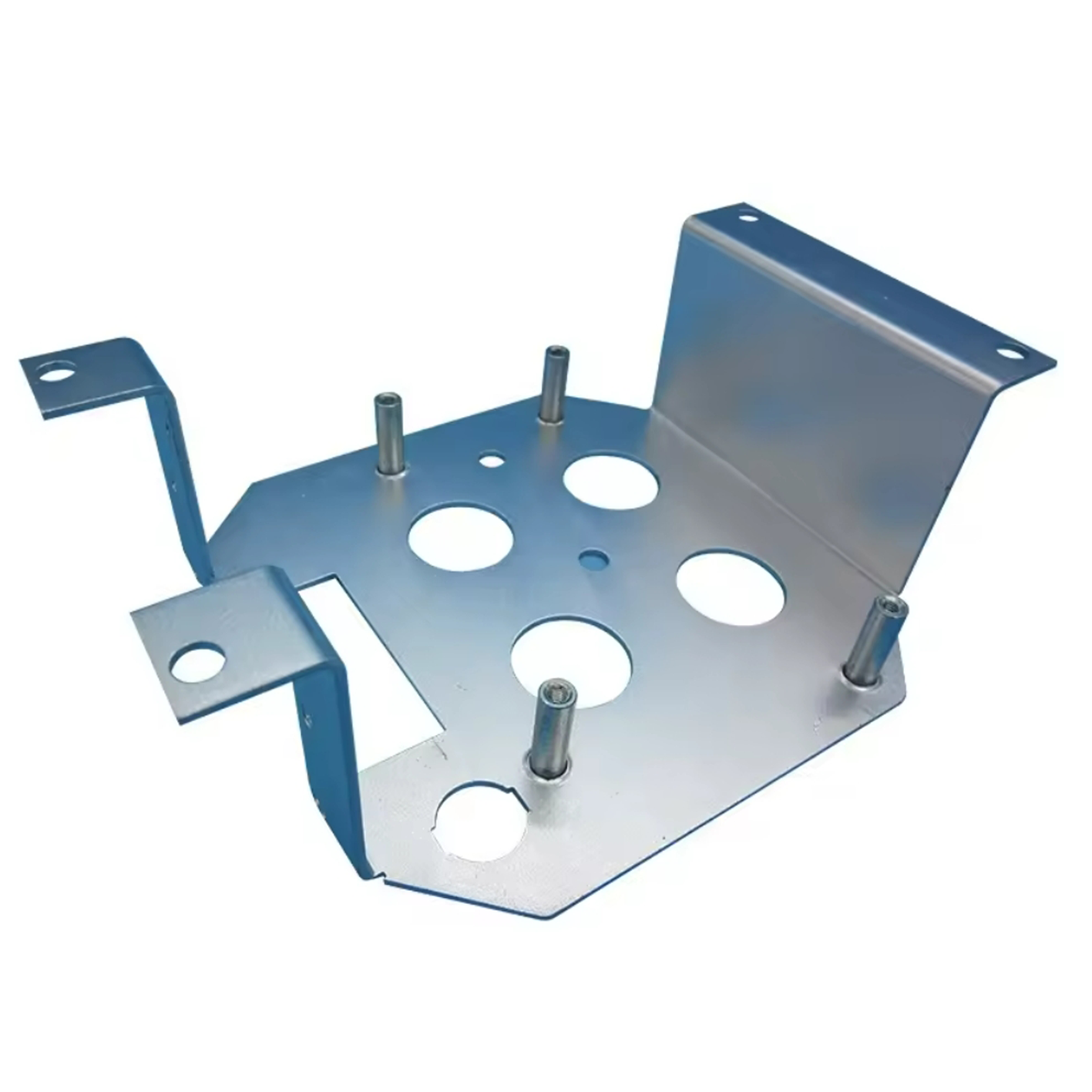

Deep draw stamping is an essential manufacturing process that enables the production of high-precision metal components with complex shapes. This technique is widely utilized across various industries, including automotive, aerospace, and electronics. The process involves a metal sheet being drawn into a die, allowing manufacturers to create intricate parts that meet specific design requirements. As global markets continue to demand quality and efficiency, partnering with an experienced deep draw stamping manufacturer becomes crucial for businesses looking to enhance their product offerings. When selecting a deep draw stamping service provider, buyers should consider factors such as technical expertise, manufacturing capabilities, and material options. A reliable manufacturer should possess advanced machinery and skilled personnel who are adept at handling diverse materials, including aluminum, steel, and stainless steel. Additionally, the ability to accommodate various production volumes, from prototype to mass production, ensures that businesses can scale their operations without compromising quality or lead times. Furthermore, a commitment to quality assurance is vital in deep draw stamping. A reputable manufacturer implements stringent quality control processes to ensure each component meets the required specifications and industry standards. By collaborating with a trusted deep draw stamping service, companies can not only achieve high-quality results but also maintain competitive pricing and timely delivery, ultimately positioning themselves for success in the global marketplace.

Deep Draw Stamping Manufacturer Service

| Process Type | Material (Common) |

Thickness Range (mm) |

Applications | Surface Treatment |

|---|---|---|---|---|

| Deep Draw Stamping | Aluminum | 0.5 - 3.0 | Automotive Parts | Anodizing |

| Progressive Die Stamping | Steel | 0.8 - 4.0 | Electronic Housings | Galvanizing |

| Single Stage Stamping | Copper | 0.3 - 2.0 | Connectors | Electroplating |

| Extra Deep Draw Stamping | Stainless Steel | 1.0 - 5.0 | Medical Devices | Passivation |

Related Products