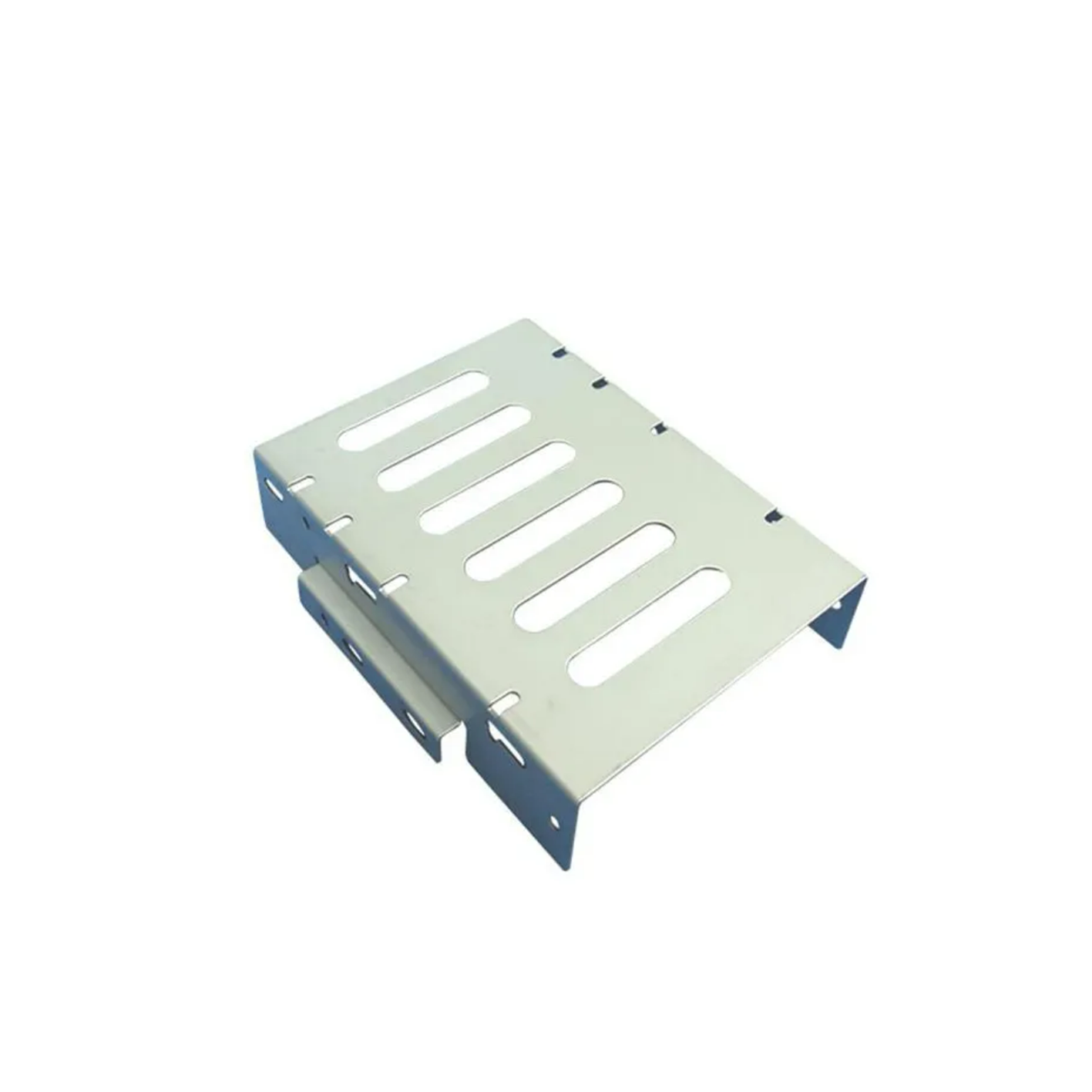

Elevator Bracket Processing Factory: OEM Solutions from Trusted Suppliers

As an expert in elevator bracket processing, I understand the importance of precision and quality in every part you source. Our factory specializes in custom OEM solutions, ensuring that each bracket meets your specific requirements. With years of experience in the industry, we’ve built strong relationships with reliable suppliers, allowing us to provide top-notch materials and craftsmanship. We prioritize your needs and work closely with you to ensure that every product not only meets but exceeds your expectations. Our facility is equipped with advanced machinery and skilled technicians dedicated to delivering excellent results. Whether you’re looking for standard brackets or unique designs, we can help you find the perfect solution to suit your project. Trust us as your go-to partner for all your elevator bracket processing needs. Let's elevate your projects together with our reliable and efficient manufacturing services!

Elevator bracket processing factory Dominates Your End-to-End Solution

In today’s fast-paced industrial landscape, finding a reliable partner for manufacturing elevator brackets is crucial for businesses aiming to streamline their operations. By leveraging cutting-edge technology and a commitment to quality, an exceptional factory provides an end-to-end solution tailored to the needs of global buyers. With expertise in precision metal processing, the factory ensures each product meets stringent industry standards, thereby enhancing safety and performance in elevator systems. Moreover, the factory's comprehensive approach to production encompasses design, fabrication, and finishing processes. This holistic strategy guarantees that every aspect of the bracket manufacturing is handled, allowing clients to focus on their core business activities. By offering customization options, the factory can cater to specific requirements, ensuring that each solution is not only effective but also fits seamlessly into various applications. Partnering with a top-notch elevator bracket processing factory means you gain access to not just products, but also invaluable industry knowledge and support throughout the procurement process. With a strong emphasis on reliability and customer satisfaction, companies can rest assured that their operational needs will be met with efficiency and professionalism. As global buyers continue to seek quality and cost-effective solutions, choosing the right manufacturing partner becomes a decisive factor in achieving success in the competitive market.

Elevator Bracket Processing Factory Dominates Your End-to-End Solution

| Dimension | Material | Weight (kg) | Surface Treatment | Lead Time (days) |

|---|---|---|---|---|

| 100x50x5 mm | Steel | 2.5 | Galvanized | 15 |

| 150x75x6 mm | Aluminum | 1.8 | Anodized | 20 |

| 200x100x8 mm | Stainless Steel | 3.5 | Polished | 30 |

| 120x60x5 mm | Mild Steel | 2.2 | Painted | 10 |

| 180x90x7 mm | Pressed Steel | 3.0 | Coated | 25 |

Related Products