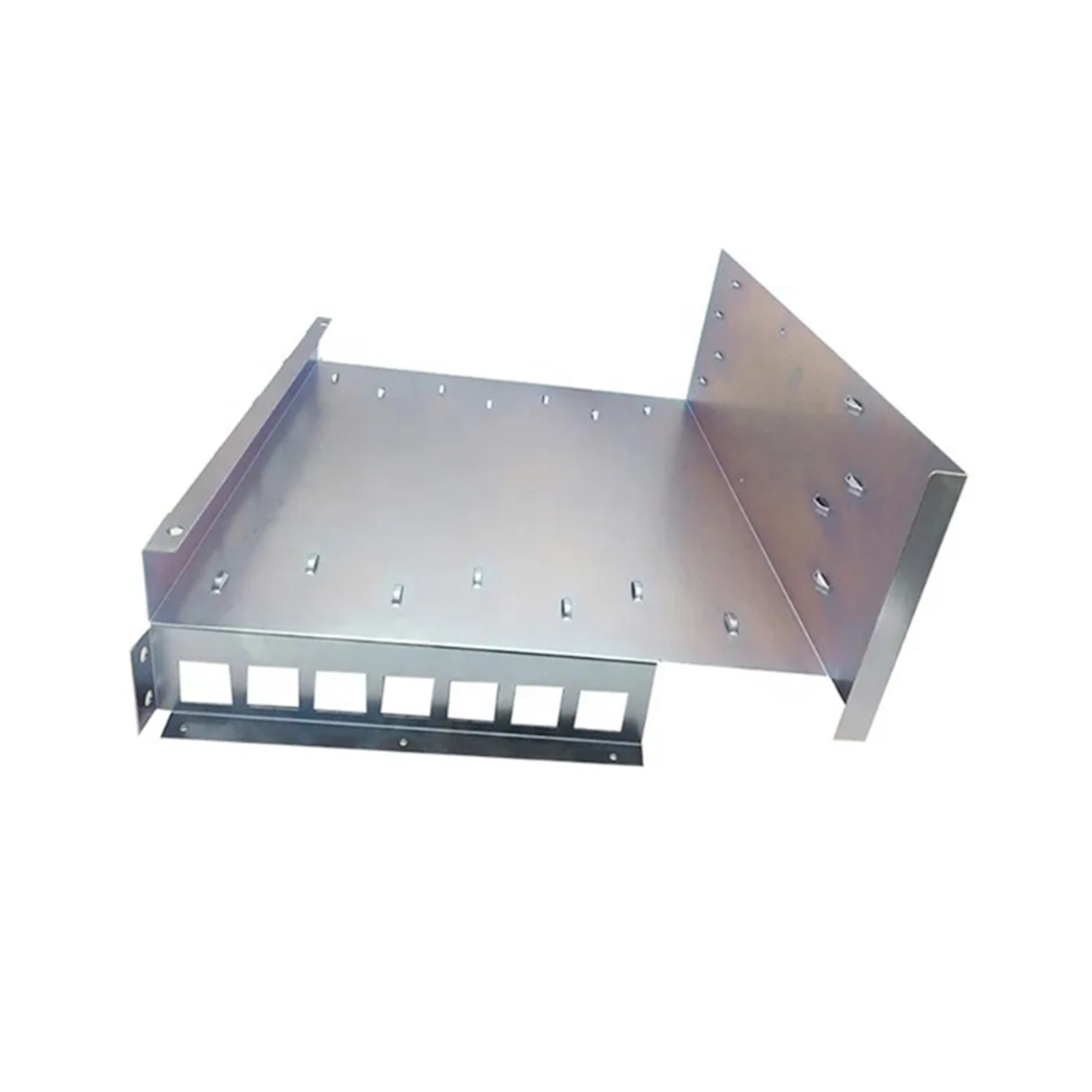

High-Quality Galvanized Bending Bracket from Trusted Supplier

When it comes to finding the perfect galvanized bending bracket, quality is key. I understand that as a B2B purchaser, you need reliability and strength in your materials. That's why I source only high-quality galvanized bending brackets that withstand the test of time and environmental conditions. These brackets are engineered with precision and are ideal for various applications in construction and manufacturing. They provide the support you need without compromising on durability. Partnering with a trusted supplier means you can count on timely deliveries and consistent stock availability, keeping your projects running smoothly. With our galvanized bending brackets, you’re not just buying a product; you’re investing in peace of mind. Our commitment to quality ensures that you’ll receive top-notch materials that help you achieve your business goals. Let’s work together to elevate your projects with the best bending brackets in the market!

Galvanized bending bracket Winning in 2025 More Than a Supplier - A Partner

In an ever-evolving global marketplace, the need for strategic partnerships is more critical than ever. As we approach 2025, organizations that prioritize collaboration with suppliers will find themselves at a significant advantage. The galvanized bending bracket is more than just a product; it's a testament to innovation and durability that can drive efficiency in your operations. By choosing a partner invested in your success, you gain access to advanced manufacturing techniques and improved product quality that directly impact your bottom line. Navigating the complexities of supply chains requires understanding not only the products but also the value of relationships. A reliable partner goes beyond just supplying goods; they provide insights, support, and customized solutions tailored to meet your specific needs. By leveraging their expertise in metal products, businesses can enhance their competitive edge, streamline processes, and ultimately achieve greater market success. As we look to the future, the role of collaboration in sourcing strategies will only intensify. Companies that view their suppliers as partners rather than mere vendors will foster deeper connections, enhancing innovation and ensuring consistent quality. The galvanized bending brackets you choose today could be the cornerstone of a partnership that propels your business into a successful 2025 and beyond.

Galvanized Bending Bracket Winning in 2025 More Than a Supplier - A Partner

| Dimension (mm) | Weight (kg) | Material Type | Surface Treatment | Load Capacity (kg) | Application Area |

|---|---|---|---|---|---|

| 100 x 50 x 3 | 1.2 | Galvanized Steel | Hot-Dip Galvanization | 500 | Construction |

| 150 x 75 x 5 | 2.0 | Galvanized Steel | Electro Galvanization | 800 | Industrial |

| 200 x 100 x 6 | 3.0 | Galvanized Steel | Hot-Dip Galvanization | 1000 | Automotive |

| 250 x 125 x 8 | 4.5 | Galvanized Steel | Electro Galvanization | 1200 | Electronics |

| 300 x 150 x 10 | 6.0 | Galvanized Steel | Hot-Dip Galvanization | 1500 | Heavy Machinery |

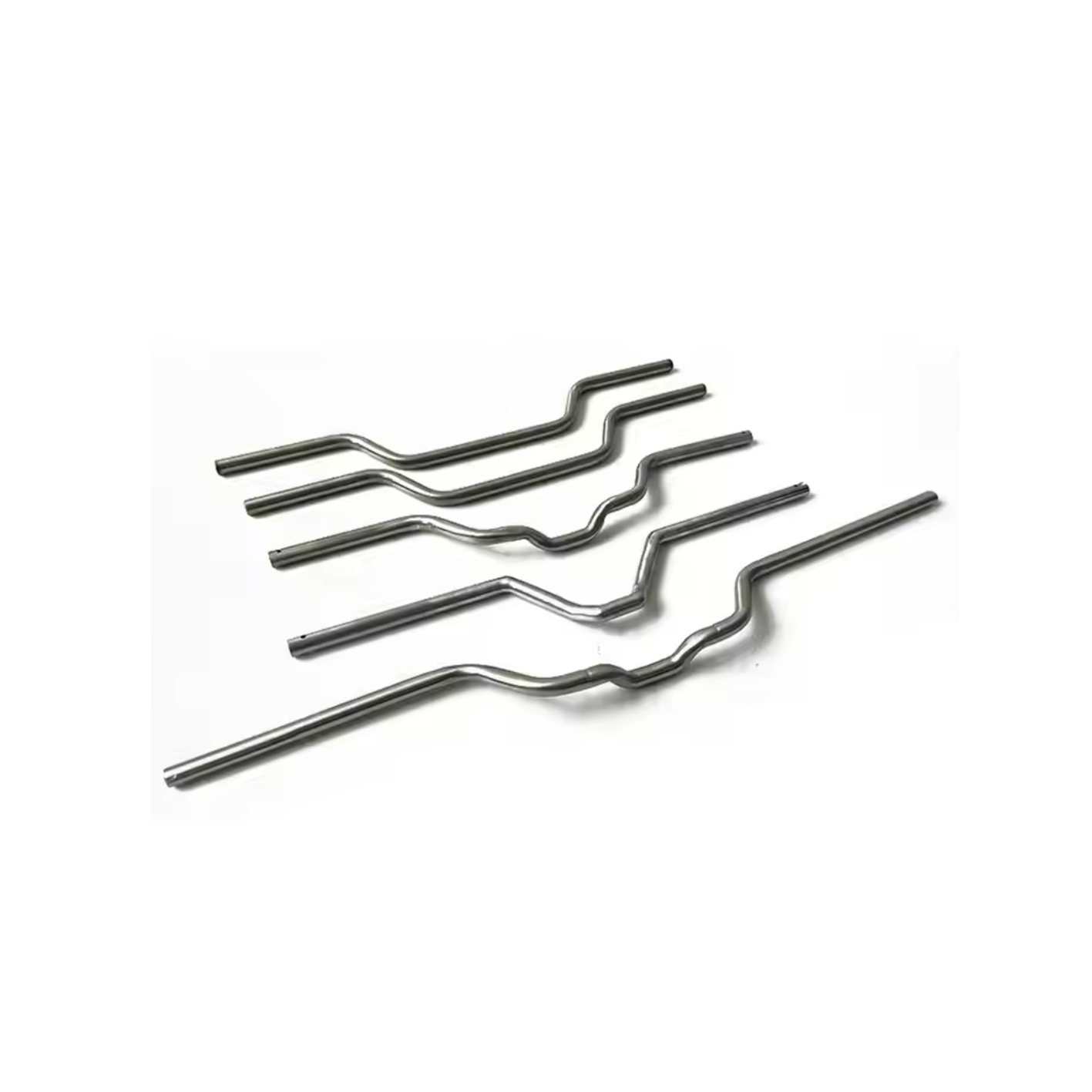

Related Products