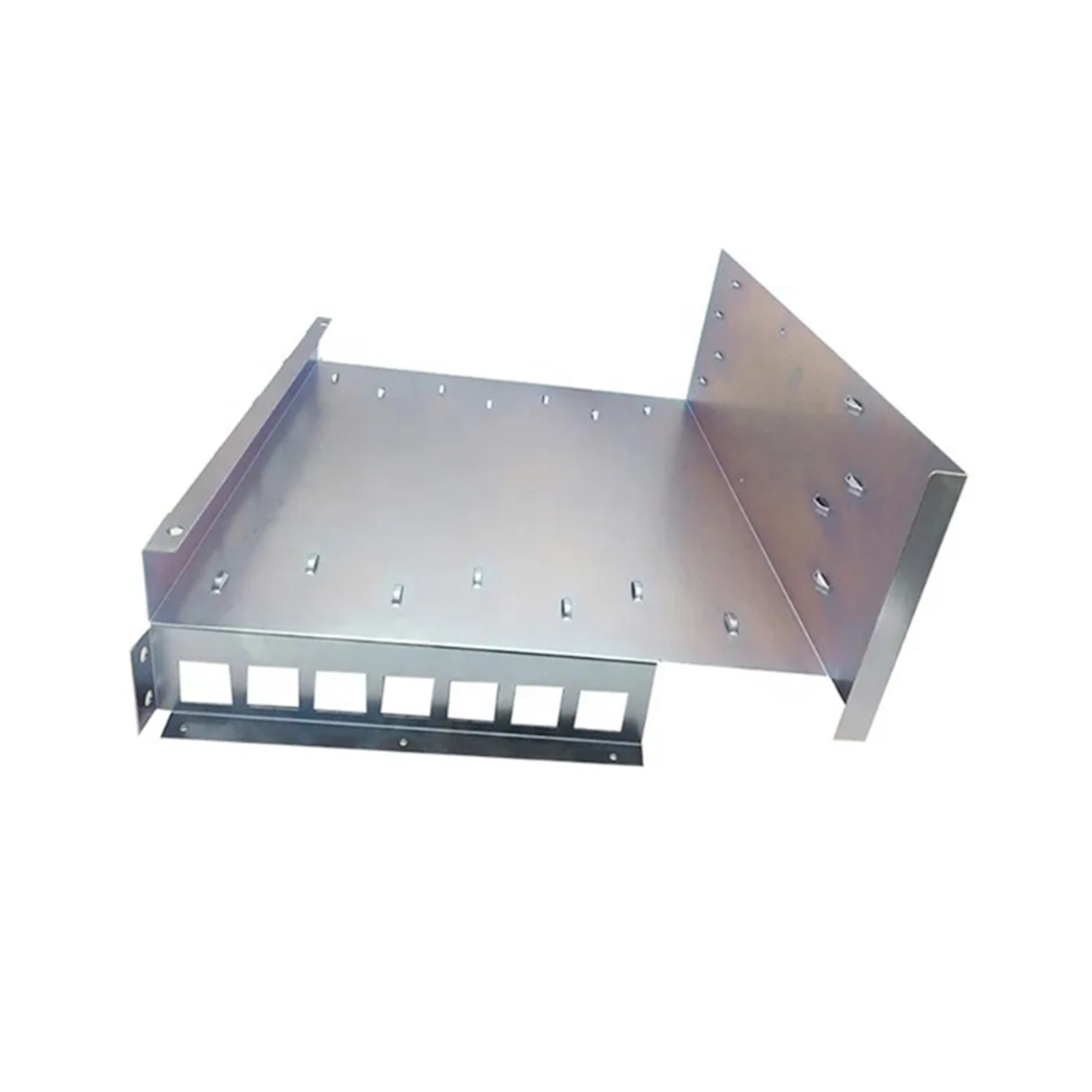

Top China Manufacturer of Quality Hardware Bending Parts for Your Needs

When it comes to sourcing high-quality hardware bending parts, I understand how crucial it is to find a reliable manufacturer in China. Our extensive range of bending components is designed to meet diverse industrial needs, ensuring durability and precision in every piece. We take pride in our advanced manufacturing processes, allowing us to deliver custom solutions tailored to your specific requirements. I invite you to explore our products, which feature exceptional craftsmanship and competitive pricing. Your satisfaction is our top priority, and we believe in building long-lasting partnerships with our clients. With years of experience in the industry, we’re equipped to support your business effectively. Let’s work together to enhance your operations with our premium hardware bending parts, all backed by our commitment to quality and service. Reach out to learn more about how we can assist you!

Hardware bending parts Manufacturer Leads the Global Market

In today's competitive manufacturing landscape, precision and quality are paramount. As one of the leading manufacturers in the hardware bending parts sector, we are dedicated to providing top-tier products that meet the diverse needs of global buyers. Our state-of-the-art production facilities utilize advanced technology and skilled craftsmanship to ensure every component meets stringent international standards, guaranteeing both durability and reliability. Our commitment to excellence does not stop at product quality. We understand the importance of timely delivery and customer support in fostering long-term partnerships. By streamlining our supply chain and optimizing production processes, we ensure that our clients receive their orders on time, every time. Our proactive approach to communication allows us to adapt quickly to changes in demand, making us a strategic partner for businesses looking to enhance their supply chain efficiency. Moreover, as sustainability becomes increasingly important in global trade, we take pride in our efforts to implement eco-friendly practices in our production methods. By prioritizing sustainable materials and reducing waste, we are not only contributing to the environment but also meeting the growing expectations of consumers for responsible sourcing. Our unwavering dedication to quality, customer satisfaction, and sustainability positions us as a trusted leader in the hardware bending parts market, ready to serve buyers across the globe.

Hardware Bending Parts Manufacturer Leads the Global Market

| Country | Market Share (%) | Production Capacity (Units/Year) | Main Material Types | Key Industries Served |

|---|---|---|---|---|

| USA | 25 | 1,000,000 | Steel, Aluminum | Automotive, Aerospace |

| Germany | 20 | 800,000 | Stainless Steel, Copper | Industrial Machinery, Electronics |

| China | 30 | 1,500,000 | Alloy Steel, Brass | Construction, Electronics |

| Japan | 15 | 600,000 | Carbon Steel, Aluminum | Automobile, Robotics |

| South Korea | 10 | 400,000 | Titanium, Aluminum | Marine, Aerospace |

Related Products