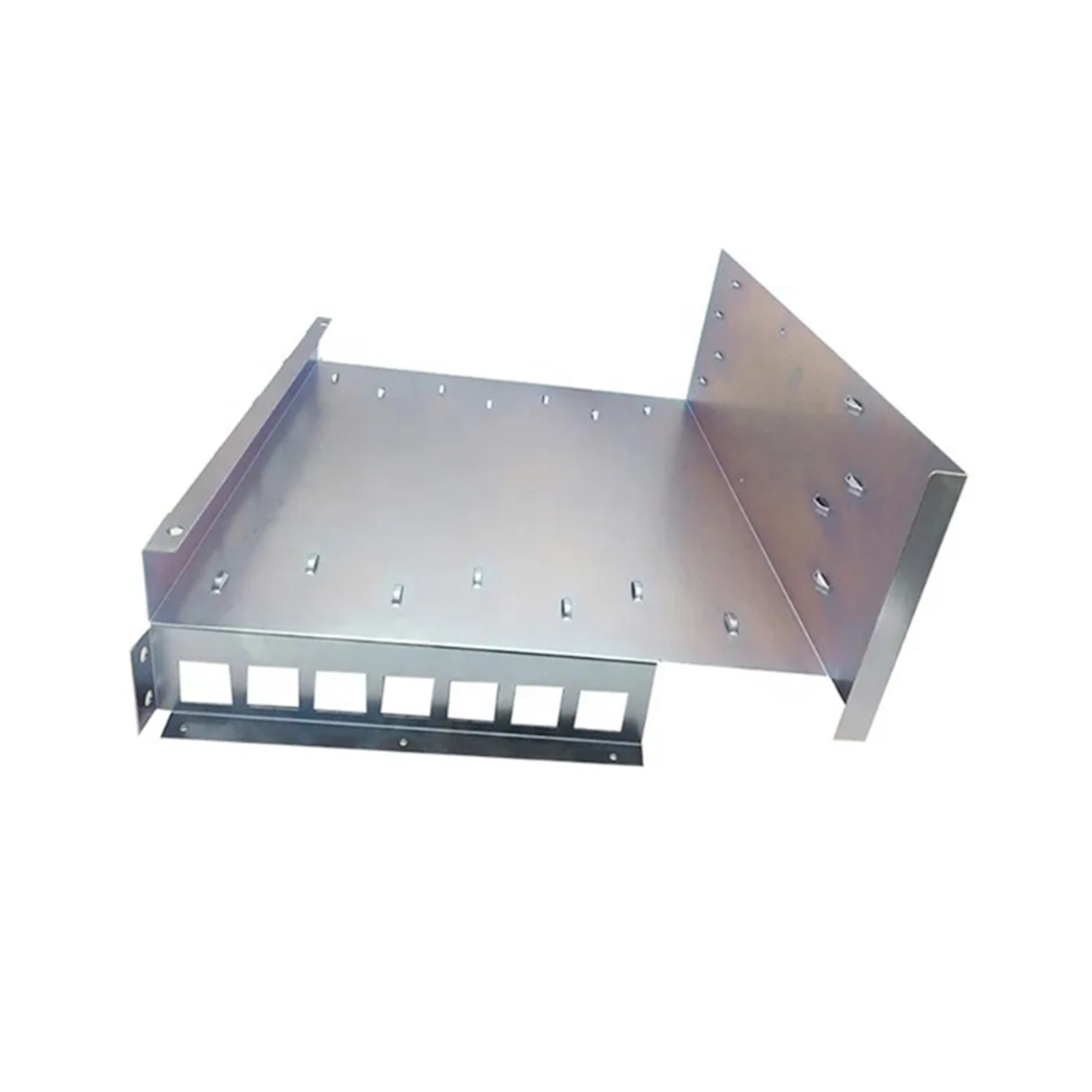

Wholesale High Precision Stainless Steel Bracket Parts Manufacturers

When it comes to sourcing high precision stainless steel bracket parts, I know how crucial quality and reliability are for your projects. Our products are crafted with the utmost attention to detail, ensuring they meet the rigorous demands of various industries. As a wholesaler, I work directly with manufacturers to create tailored solutions that fit your specific needs, saving you both time and money. Each bracket part is rigorously tested for durability and performance, allowing you to trust our products for even the most demanding applications. Whether you’re looking to scale up operations or simply need a reliable supplier, I can help make your procurement process seamless and efficient. Let's connect to explore how our high precision stainless steel bracket parts can enhance your business and ensure your projects succeed. With our commitment to excellence and customer satisfaction, I’m confident you’ll find the quality you need at a competitive price.

High precision stainless steel bracket parts Now Trending Guarantees Peak Performance

In the ever-evolving landscape of industrial manufacturing, the demand for high-precision stainless steel bracket parts is on the rise. These components play a crucial role in a variety of applications, from automotive to aerospace, due to their strength, durability, and corrosion resistance. As global procurement professionals seek reliable suppliers, the emphasis on quality and performance cannot be overstated. High-precision stainless steel brackets are engineered to meet the stringent requirements of modern engineering applications. Their ability to withstand extreme conditions while maintaining structural integrity makes them an essential choice for manufacturers focused on longevity and reliability. With innovative production techniques and rigorous quality control measures, these components not only ensure peak performance but also contribute to operational efficiency and cost savings for businesses. As industries continue to prioritize sustainability and efficiency, the shift towards high-quality, precision-engineered stainless steel components is becoming increasingly vital. By investing in these trending bracket parts, manufacturers can optimize their production processes and achieve a competitive edge in the global market. Embracing the advantages of high-precision components will not only enhance product performance but also foster stronger supplier relationships built on trust and reliability.

High Precision Stainless Steel Bracket Parts Now Trending Guarantees Peak Performance

| Part Name | Material | Manufacturing Process | Dimensional Tolerance | Surface Finish |

|---|---|---|---|---|

| Bracket A | Stainless Steel 304 | CNC Machining | ±0.02 mm | Brushed |

| Bracket B | Stainless Steel 316 | Laser Cutting | ±0.03 mm | Polished |

| Bracket C | Stainless Steel 410 | Stamping | ±0.05 mm | Galvanized |

| Bracket D | Stainless Steel 430 | Bending | ±0.04 mm | Anodized |

Related Products