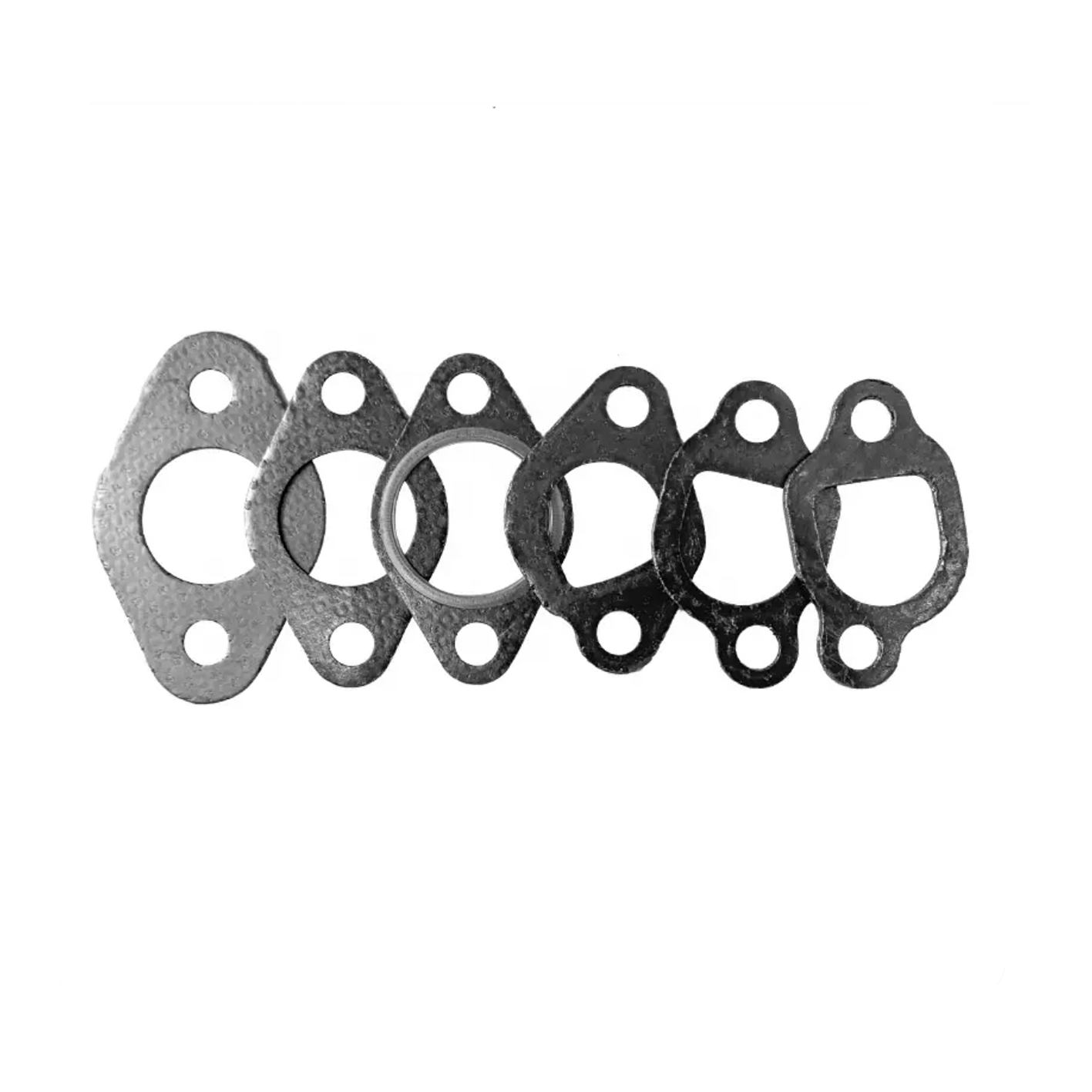

High Temperature Resistance Gaskets Manufacturer in China - Quality Assured

When it comes to high temperature resistance gaskets, I know that finding a reliable manufacturer in China is crucial for your business needs. Our gaskets are specifically designed to withstand extreme temperatures while providing excellent sealing performance. I have personally overseen the production process to ensure that every gasket meets the highest quality standards. With a focus on durability and reliability, these gaskets are perfect for various industries, including automotive, aerospace, and manufacturing. What sets us apart is our commitment to customization; we can tailor the gaskets to suit your specific requirements. I understand the importance of maintaining efficiency in your operations, and our products are built to enhance that. By choosing our high temperature resistance gaskets, you are partnering with a manufacturer who puts your needs first. Let’s connect and discuss how we can support your business’s success with our top-quality gaskets!

high temperature resistance gaskets Industry Leaders Sets the Industry Standard

In the realm of high temperature resistance gaskets, setting the industry standard is not merely about adhering to specifications; it is about innovation, reliability, and understanding the unique needs of diverse applications. As industries continue to evolve, the demand for gaskets that can withstand extreme conditions while maintaining integrity becomes increasingly critical. Leading manufacturers are now focusing on advanced materials and cutting-edge technology to provide solutions that meet these stringent requirements. One of the major factors driving the industry's growth is the emphasis on customization. Procurement professionals are seeking gaskets that not only meet high temperature thresholds but are also tailored to specific operational demands. This is where collaboration between manufacturers and clients plays a vital role. By engaging in detailed discussions about application scenarios, organizations can develop products that offer enhanced performance and longevity, thereby reducing maintenance costs and improving overall efficiency. Furthermore, sustainability is becoming a significant consideration for purchasing decisions. As more companies strive for eco-friendly practices, the demand for gaskets made from sustainable materials is rising. Industry leaders are stepping up by investing in research and development to create products that not only perform under extreme conditions but also align with environmental standards. In this landscape, selecting a partner that prioritizes both quality and responsible manufacturing practices is key for global buyers looking to stay ahead in their respective markets.

High Temperature Resistance Gaskets Industry Leaders Sets the Industry Standard

| Material | Temperature Resistance (°C) | Applications | Certifications |

|---|---|---|---|

| Silicone | -60 to 230 | Automotive, Aerospace | ISO 9001 |

| PTFE | -200 to 260 | Chemical Processing, Food Industry | FDA, RoHS |

| Fiberglass | -50 to 600 | Power Generation, Oil & Gas | ASTM, API |

| Graphite | -200 to 450 | Heat Exchangers, Steam Equipment | DIN, ISO |

| Rubber | -20 to 120 | Construction, HVAC | UL94 |

Related Products