ODM Leaf Spring Factory – Iron plate deep drawing parts manufacturer – Xinzhe

ODM Leaf Spring Factory – Iron plate deep drawing parts manufacturer – Xinzhe Detail:

Description

Description

How do wrinkling and cracking occur in the deep drawing process, and how to prevent them?( aluminum welding)

The greater the magnitude of the tangential compressive stress, the easier it is to lose stability and wrinkle; the greater the flange width and the thinner the thickness, the smaller the elastic modulus and hardening modulus of the material. The less stable the ability is.( deep drawing/ deep draw stamping/ sheet metal pressing)

The main method is to use a pressing device on the mold structure to press the edge ring, so that the part of the blank that may wrinkle is sandwiched between the die plane and the edge ring, so that the blank can pass between the two planes smoothly. The use of pressing ribs or deep drawing sills can also effectively increase the radial tensile stress and reduce the effect of tangential compressive stress, and it is also an effective measure for anti-wrinkle.( deep draw metal stamping/ sheet metal forming)

As the punch continues to descend, the outer diameter of the blank left on the end face of the die shrinks continuously, and the circular blank is gradually pulled into the gap between the punch and the die to form a straight wall, while the material under the punch becomes a puller. For the bottom of the deep part, when all the sheet metal enters the gap between the convex and concave dies, the drawing process ends, and the flat blank becomes a cup-shaped part with a certain diameter and height.( sheet metal shaping/ sheet metal pressing/ forming sheet)

Compared with the blanking die, the working parts of the deep drawing convex and concave dies should not have sharp edges, but have certain rounded corners, and the unilateral gap between the convex and concave dies is slightly larger than the material thickness.( sheet metal fabrication/ custom metal fabrication)

Extended information:

After deep drawing, the thickness and hardness of the wall of the simplified shape will change. The thickness of the upper part of the side wall of the circular piece increases the most, up to 20%~30%; while the minimum thickness of the plate thickness decreases up to 8%~10% at the place slightly above the corner of the wall and the bottom. When the stress of this section exceeds the strength limit of the material at this time, the workpiece is pulled and cracked here.( aluminum fabrication/ aluminum welding shops near me)

The formation mechanism of pull marks and pull cracks is the same, the only difference is that the degree of the two is different. When the ingot is pulled down from the crystallization tank to the casting well after the melt crystallizes, the strength of the metal solidification crust formed just after crystallization of the melt in the crystallization tank is low.( stainless steel fabrication/ welding metal fabrication)

It is not enough to resist the friction between the ingot and the working surface of the crystallization tank, and the surface of the ingot will be pulled out of streaks. In severe cases, the surface of the ingot will be pulled out of the crack horizontally. (fabrication and welding/ welding metal/ welding stainless steel)

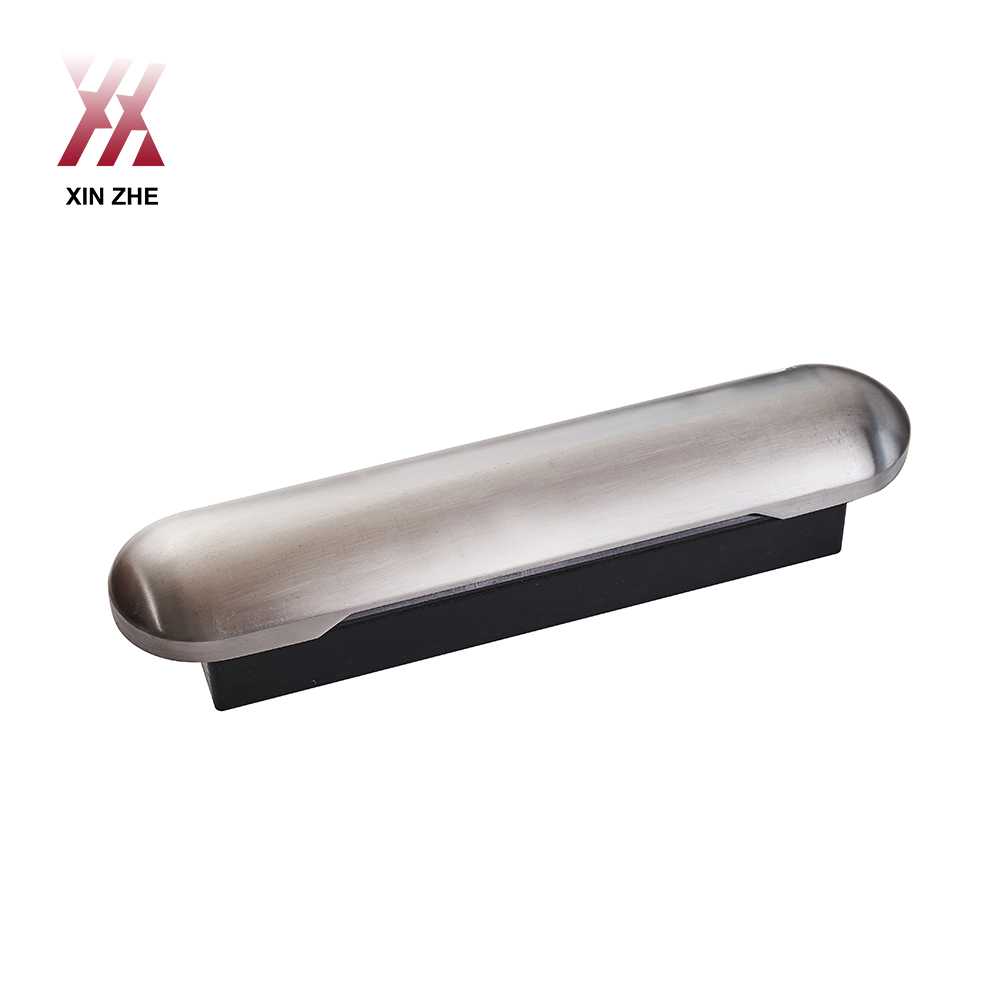

Product detail pictures:

Related Product Guide:

We have been proud from the higher consumer gratification and wide acceptance due to our persistent pursuit of high quality both on product or service and service for ODM Leaf Spring Factory – Iron plate deep drawing parts manufacturer – Xinzhe , The product will supply to all over the world, such as: Plymouth, San Francisco, Congo, We take measure at any expense to achieve essentially the most up-to-date equipment and approaches. The packing of nominated brand is our a further distinguishing feature. The products to assure years of trouble-free service has attracted a great deal customers. The solutions are obtainable in improved designs and richer assortment, they're created scientifically of purely raw supplies. It readily available in a variety of designs and specifications for your selection. The most recent kinds are a great deal better than the preceding one particular and they are quite popular with lots of prospects.

Speaking of this cooperation with the Chinese manufacturer, I just want to saywell dodne, we are very satisfied.