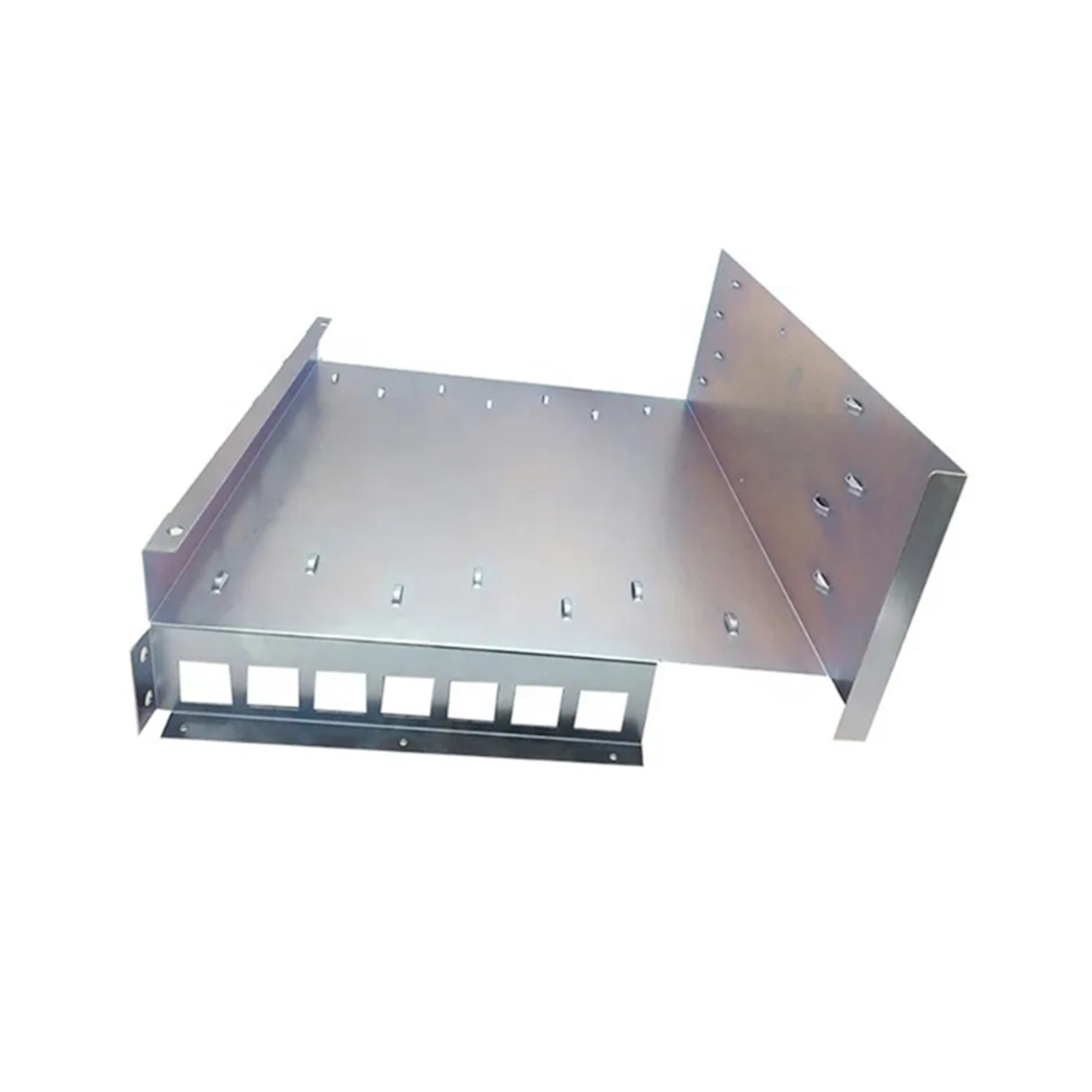

China Manufacturer of Spray-Coated Bending Brackets for Durability

When I first came across the spray-coated bending brackets, I immediately understood their value in enhancing structural integrity and durability. Crafted from high-quality materials, these brackets are perfect for various applications, from construction to furniture design. Sourced from leading manufacturers in China, each product undergoes strict quality checks to ensure you receive only the best. I appreciate how the spray coating not only prevents corrosion but also enhances the aesthetic appeal of the brackets. If you are seeking reliable components that can stand the test of time and utilize cutting-edge manufacturing processes, then these brackets should be on your list. They are designed to meet the demanding needs of B2B purchasers, ensuring that your projects succeed with top-notch materials. Don’t settle for less when quality and performance are what you deserve. Grab your spray-coated bending brackets today and elevate your next project!

Spray-coated bending bracket Ahead of the Curve Sets the Industry Standard

In the ever-evolving landscape of metal products, innovation and quality are paramount. The introduction of spray-coated bending brackets has set a new benchmark, seamlessly combining durability with aesthetic appeal. These brackets not only offer exceptional strength and flexibility but also feature a protective coating that enhances their resistance to corrosion and wear, making them ideal for both indoor and outdoor applications. Global buyers seeking reliable and high-performance components will find these brackets to be a perfect fit for their diverse needs, from construction projects to industrial machinery. Moreover, the adoption of advanced manufacturing techniques ensures that these spray-coated bending brackets meet rigorous quality standards while providing a cost-effective solution. With a focus on precision engineering, each piece is designed to endure heavy loads and dynamic forces, making them suitable for various industries such as automotive, aerospace, and structural fabrication. By prioritizing sustainability and efficiency, manufacturers are paving the way for environmentally friendly practices without compromising on performance. As global sourcing becomes more competitive, investing in high-quality products like spray-coated bending brackets can give businesses a significant advantage. Collaborating with trustworthy suppliers who emphasize innovation and quality assurance will not only enhance product offerings but also strengthen market position. Embrace the future of metal products and ensure your projects are equipped with components that offer both reliability and cutting-edge technology.

Spray-coated Bending Bracket Ahead of the Curve Sets the Industry Standard

| Feature | Description | Benefits | Applications |

|---|---|---|---|

| Material | High-strength steel with spray-coated finish | Durability and corrosion resistance | Industrial machinery, construction |

| Design | Ergonomic bending shape for optimal load distribution | Increased structural integrity | Automotive, aerospace components |

| Finish | Smooth, even spray coating | Aesthetic appeal and superior protection | Consumer products, machinery |

| Weight | Lightweight for ease of handling | Reduced shipping and installation costs | Portable equipment, automation |

| Customization Options | Available in various sizes and finishes | Meets specific project requirements | Construction, custom fabrication |

Related Products