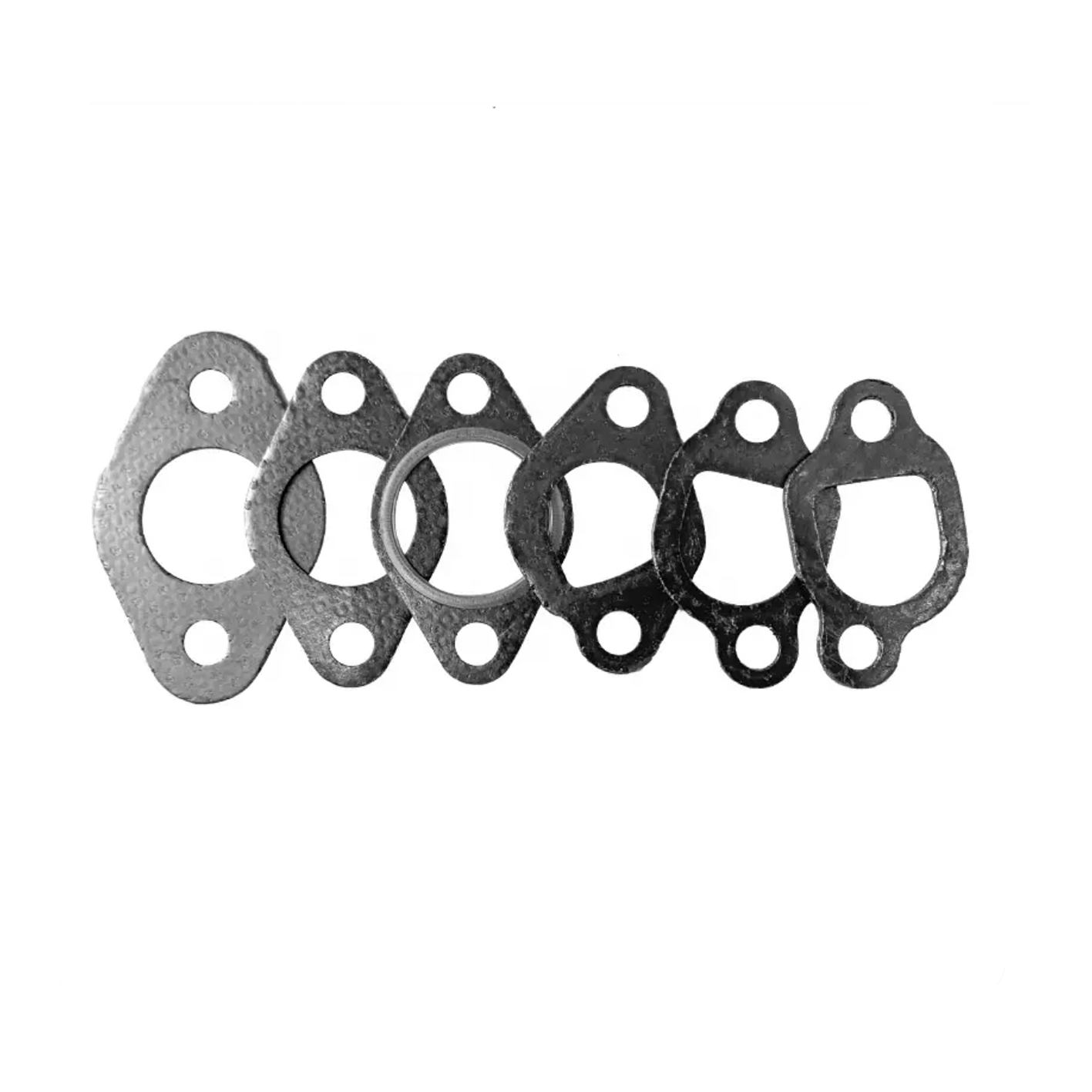

Custom Graphite Gaskets from Leading China Manufacturer - High Quality Solutions

When it comes to reliable sealing solutions, I can't stress enough the importance of custom graphite gaskets. Sourced directly from reputable manufacturers in China, these gaskets are designed to meet specific industry needs. They offer superior thermal conductivity and chemical resistance, making them perfect for a wide array of applications. My experience shows that clients appreciate the tailored approach we take, ensuring that each gasket fits the unique requirements of their operations. Whether you are in the automotive, aerospace, or energy sector, you'll find our custom graphite gaskets provide an excellent balance of performance and durability. Choosing a gasket made with high-quality materials not only enhances efficiency but also reduces maintenance costs in the long run. If you're aiming for top-notch solutions, aligning with a trusted manufacturer in China can truly elevate your sealing processes. Let’s work together to find the perfect custom graphite gasket for your business needs.

custom graphite gasket Where Service Meets Innovation More Than a Supplier - A Partner

In the evolving landscape of industrial components, custom graphite gaskets are emerging as essential elements in enhancing efficiency and sustainability across various sectors. As procurement professionals seek reliable partnerships, it becomes vital to choose a supplier that not only provides high-quality products but also understands the intricate needs of their clients. Here, innovation meets expertise, fostering a collaborative environment where your challenges become shared opportunities for growth and improvement. Our approach goes beyond mere supplier dynamics; we believe in establishing long-term partnerships. Understanding that each industry has unique requirements, we offer tailor-made solutions designed to meet specific applications. Our commitment to innovation ensures that we continuously explore the latest technologies and processes, allowing us to deliver products that enhance operational efficiency and reduce downtime. When you choose a partner in your supply chain, you're investing in a relationship that supports your goals, promotes sustainability, and drives competitive advantages. We recognize that today’s buyers are looking for more than just products—they seek consultative partnerships that bring added value. By engaging in close collaboration with clients, we not only craft exceptional graphite gaskets but also provide insights and guidance that help optimize performance and reduce costs. This holistic approach ensures that our clients are not only well-equipped to meet current demands but are also prepared for future challenges in a rapidly changing market. Choosing us means choosing a partner dedicated to your success, where superior service and innovative solutions go hand in hand.

Custom Graphite Gasket - Where Service Meets Innovation More Than a Supplier - A Partner

| Material Type | Thickness (mm) | Temperature Resistance (°C) | Application | Customization Options |

|---|---|---|---|---|

| Flexitallic Gasket | 2.0 | -200 to 450 | Oil & Gas | Shape, Size, Reinforcement |

| Graphite Sheet Gasket | 3.0 | -200 to 1000 | Chemical Processing | Thickness, Size, Edge Treatment |

| Spiral Wound Gasket | 1.5 | -250 to 550 | Marine, HVAC | Material, Diameter, Inner Ring Options |

| Expanded Graphite Gasket | 4.0 | -250 to 800 | Power Generation | Thickness, Custom Shapes & Sizes |

Related Products