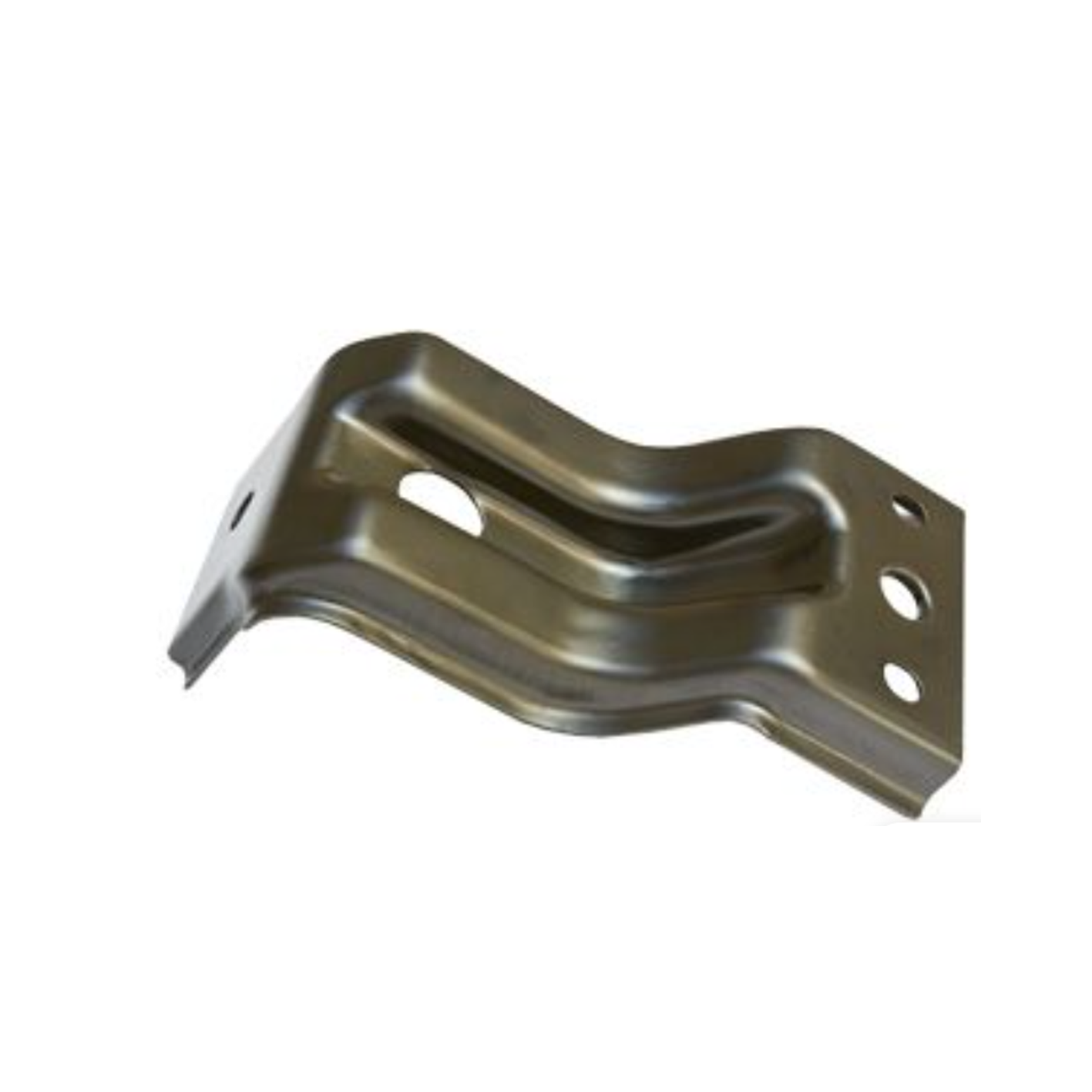

China Manufacturer of High-Quality Metal Deep Drawing Parts

If you’re in need of high-quality metal deep drawing parts, I can help you find exactly what you're looking for. Sourced directly from a reliable manufacturer in China, our parts are crafted using advanced techniques to ensure precision and durability. I understand how critical it is for businesses like yours to receive parts that meet specific requirements and timelines. Our metal deep drawing components are perfect for various applications, providing strength and reliability you can trust. Whether you’re in automotive, aerospace, or any other industry, my commitment is to deliver parts that not only meet but exceed your expectations. Plus, working with a manufacturer in China allows us to offer competitive pricing without sacrificing quality. Let's connect and discuss how we can fulfill your needs for metal deep drawing parts efficiently and effectively. Your success is my priority, and I’m here to assist you every step of the way.

metal deep drawing parts Guarantees Peak Performance Exceeds Industry Benchmarks

When it comes to metal deep drawing parts, achieving peak performance is not just a goal; it's an expectation. As industries across the globe strive for excellence, the demand for components that not only meet but exceed industry benchmarks is rising. This is where precision engineering and innovative manufacturing processes come into play. The synergy between advanced technology and skilled craftsmanship ensures that metal deep drawing parts are produced with exceptional quality and reliability, catering to the diverse needs of global procurement. Manufacturers that prioritize precision in deep drawing techniques are more capable of fulfilling complex design requirements. This method allows for the creation of intricate shapes and forms while maintaining material integrity. As a result, products can perform optimally in their respective applications, whether in automotive, aerospace, or consumer electronics. The commitment to rigorous quality standards ensures that each component not only withstands operational demands but also enhances the overall efficiency of end products. In a competitive landscape, the ability to deliver high-performing metal products sets a company apart. By focusing on continuous improvement and embracing innovative practices, manufacturers can ensure that their offerings not only satisfy current market needs but also anticipate future trends. This proactive approach to product development positions organizations as leaders in the metalworking industry, making them a preferred choice for global buyers looking for superior components that drive success in their operations.

Metal Deep Drawing Parts Guarantees Peak Performance Exceeds Industry Benchmarks

| Part Name | Material Type | Thickness (mm) | Tensile Strength (MPa) | Elongation (%) | Usage/Application |

|---|---|---|---|---|---|

| Connector Housing | Stainless Steel | 1.2 | 550 | 20 | Automotive |

| Chassis Bracket | Aluminum Alloy | 2.0 | 300 | 15 | Structural |

| End Cap | Carbon Steel | 1.5 | 400 | 25 | Piping Systems |

| Shell | Copper | 1.0 | 210 | 30 | Electronics |

Related Products