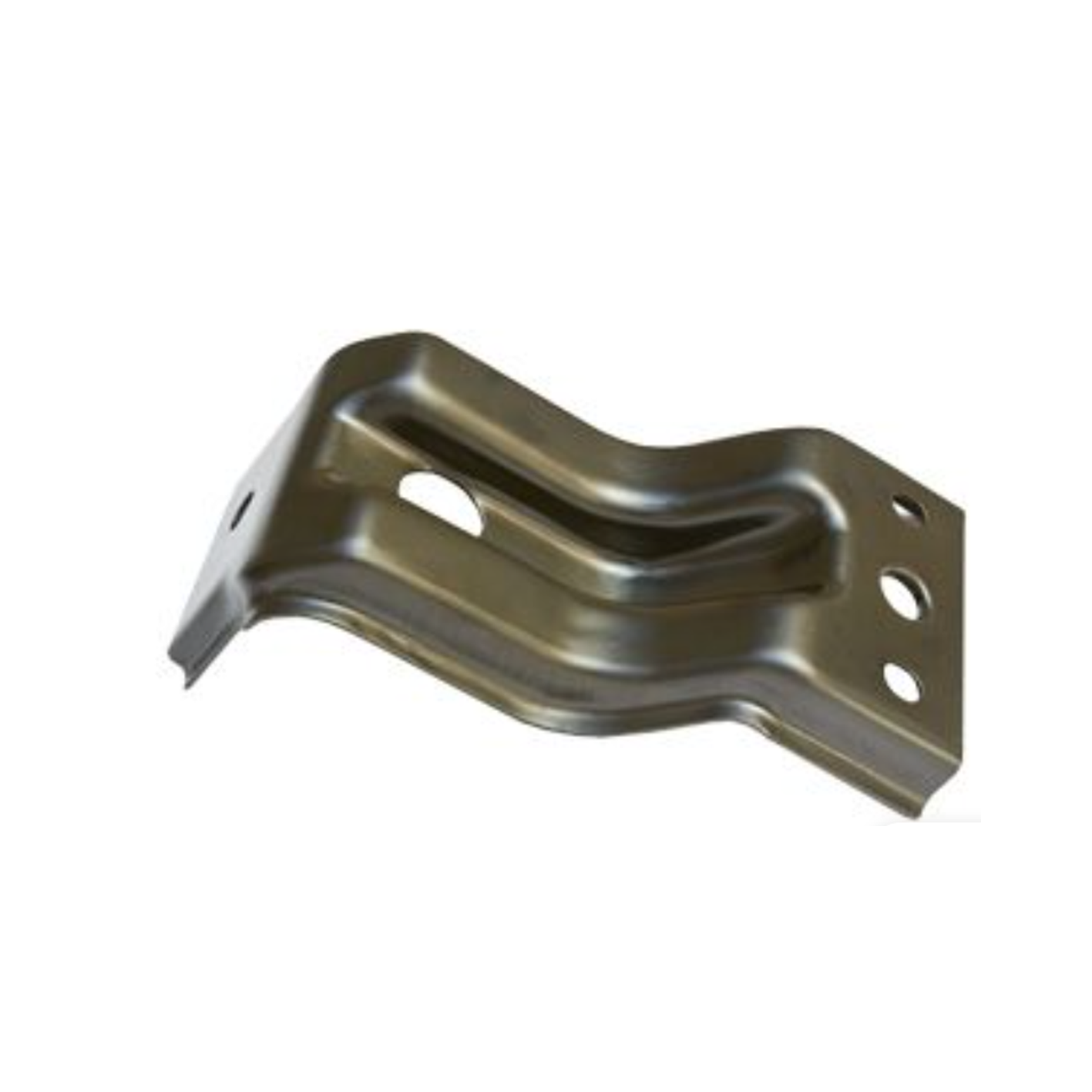

Customized aluminum alloy sheet metal bending products

Description

| Product Type | customized product | |||||||||||

| One-Stop Service | Mold development and design-submit samples-batch production-inspection-surface treatment-packaging-delivery. | |||||||||||

| Process | stamping,bending,deep drawing,sheet metal fabrication,welding,laser cutting etc. | |||||||||||

| Materials | carbon steel,stainless steel,aluminum,copper,galvanized steel etc. | |||||||||||

| Dimensions | according to customer's drawings or samples. | |||||||||||

| Finish | Spray painting, electroplating, hot-dip galvanizing, powder coating, electrophoresis, anodizing, blackening, etc. | |||||||||||

| Application Area | Auto parts, agricultural machinery parts, engineering machinery parts, construction engineering parts, garden accessories, environmentally friendly machinery parts, ship parts, aviation parts, pipe fittings, hardware tool parts, toy parts, electronic parts, etc. | |||||||||||

Advantags

1. More than 10 years of overseas trade expertise.

2. Provide one-stop service from mold design to product delivery.

3. Fast delivery time, about 30-40 days. In stock within one week.

4. Strict quality management and process control (ISO certified manufacturer and factory).

5. More reasonable prices.

6. Professional, our factory has more than 10 years of history in the field of metal stamping sheet metal.

Quality management

Vickers hardness instrument.

Profile measuring instrument.

Spectrograph instrument.

Three coordinate instrument.

Shipment Picture

Production Process

01. Mold design

02. Mould Processing

03. Wire cutting processing

04. Mold heat treatment

05. Mold assembly

06. Mold debugging

07. Deburring

08. electroplating

09. Product Testing

10. Package

Introduction to elevator materials

Commonly used metal materials in elevators mainly include stainless steel, alloy structural steel, carbon structural steel, aluminum alloy, copper, cold-drawn profiles, hot-rolled profiles, etc. The following is a detailed introduction:

Stainless steel: It is corrosion-resistant, wear-resistant and easy to clean. It is often used in elevator door leaves, door side strips and other parts.

Alloy structural steel and carbon structural steel: They have high strength and toughness and are used to withstand the load of elevators. They are often used in elevator door frames, door frames and other parts.

Aluminum alloy has light weight, high strength and good plasticity, and is used in elevator ceilings and wall panels.

Copper: It is used in the circuit and conductive parts of elevators and has the characteristics of anti-oxidation, sound and heat conduction.

Cold-drawn profiles and hot-rolled profiles: They have high strength, wear resistance, resistance to deformation, high strength and hardness respectively, and are used in the production of elevator guide rails.

The application of different metal materials will vary according to the purpose, model and brand of the elevator. When selecting suitable metal materials, you need to consider ensuring the safety performance of the elevator.

Why choose us

1.Expert sheet metal fabrication and metal stamping parts for more than a decade.

2. A high grade of production is something we focus on more.

3. Outstanding support available around-the-clock.

4. Within a month, delivery occurs quickly.

5. A robust technical team that supports and backs up research and development.

6. Propose OEM collaboration.

We receive positive comments from our consumers and very few complaints.

8. Every product has good mechanical properties and a decent lifespan.

9. A competitive pricing that is appropriate.