Sewing Machine Stamping Parts Manufacturer in China: Quality Solutions

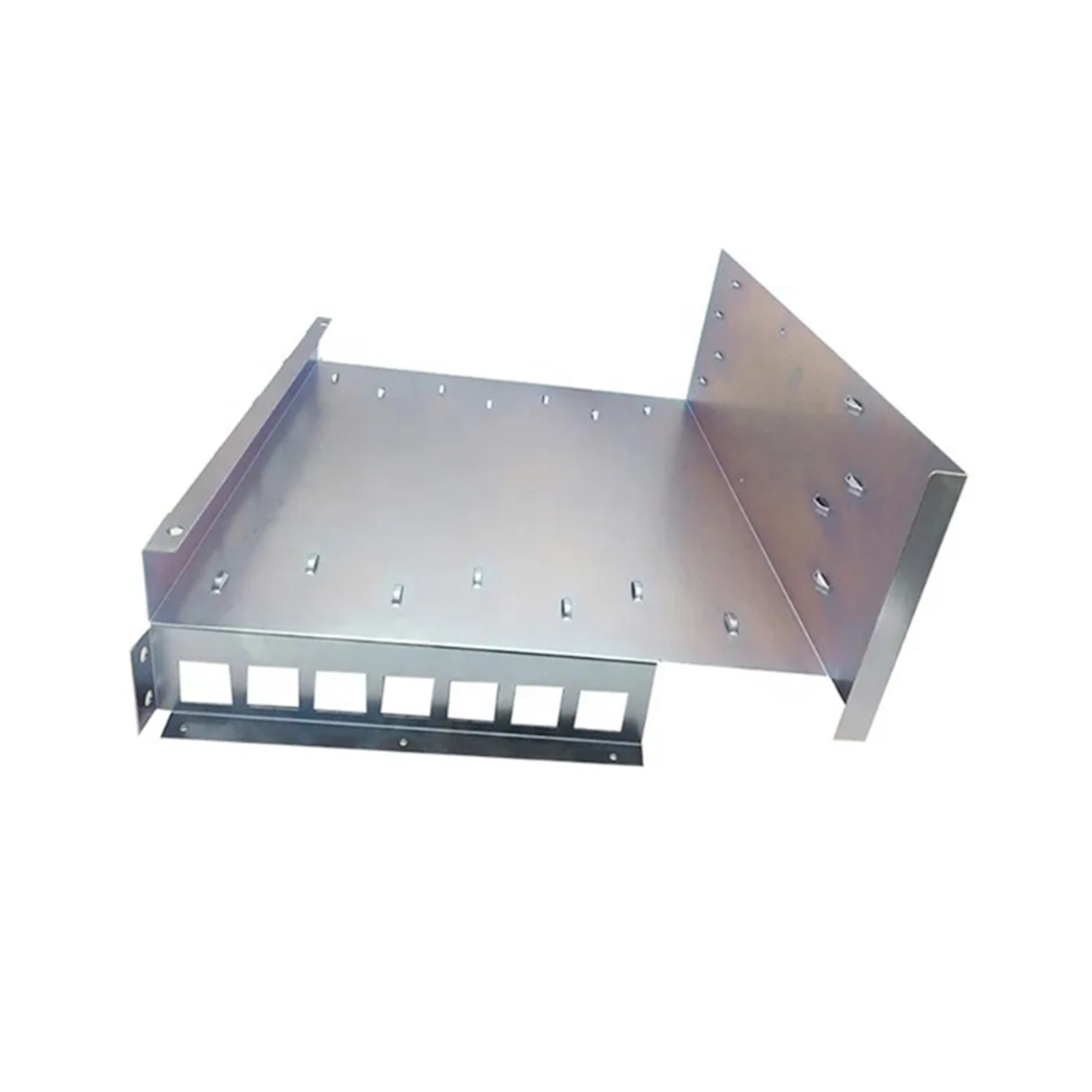

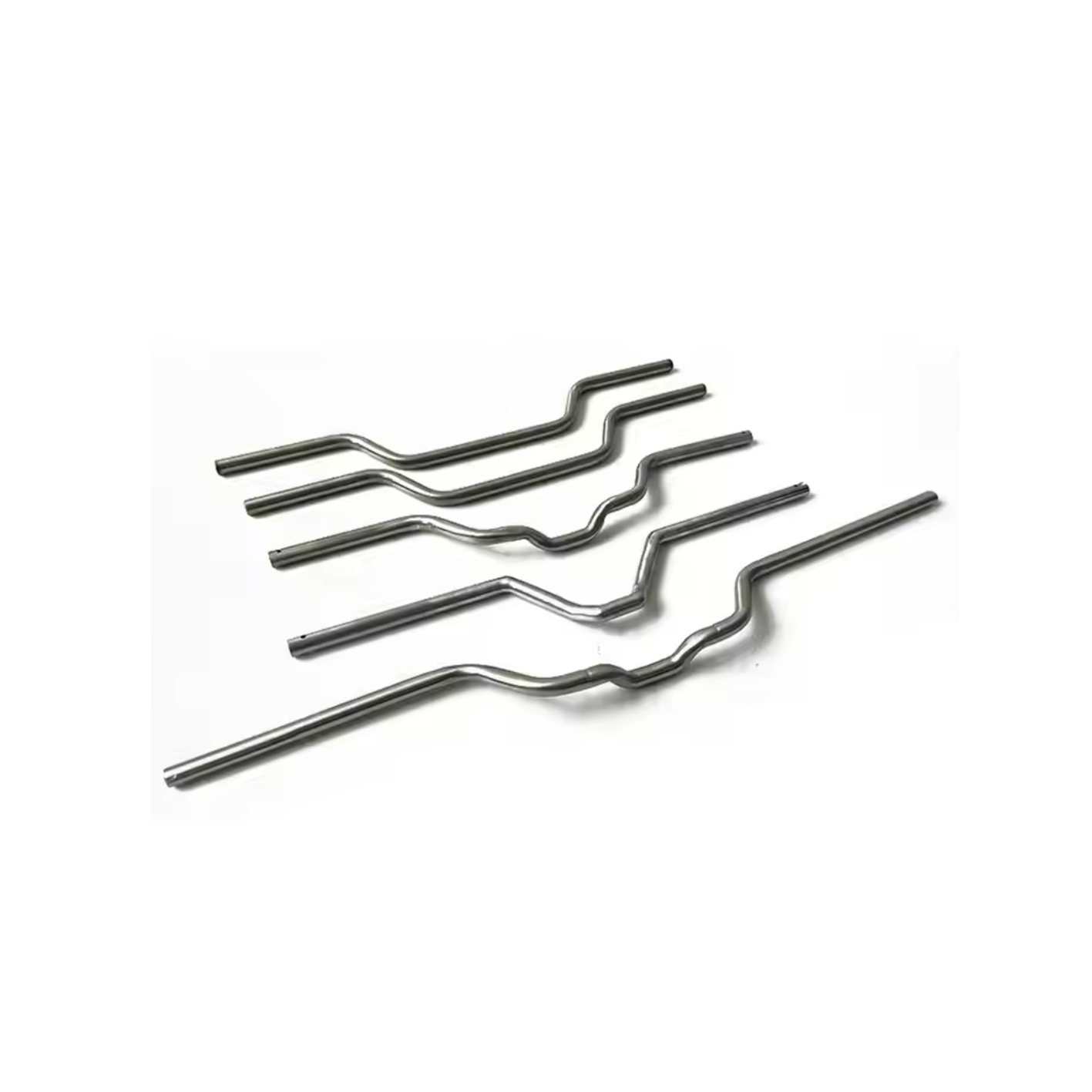

When it comes to high-quality sewing machine stamping parts, I've found that sourcing from a reliable manufacturer in China can make all the difference. Our products are designed to enhance the performance and durability of your sewing machines, ensuring optimal efficiency in your operations. With years of experience in the industry, we understand the specific needs of B2B purchasers like you. Each part is crafted with precision and undergoes rigorous quality checks to meet international standards. I believe in transparency and building lasting relationships, so I'm here to support you every step of the way. Whether you are looking for custom solutions or standard parts, we’ve got you covered. Let's work together to find the perfect stamping parts that will keep your business running smoothly!

Sewing Machine Stamping Parts Guarantees Peak Performance From Concept to Delivery

When it comes to sewing machine stamping parts, achieving peak performance from concept to delivery is paramount in today’s fast-paced manufacturing landscape. High-quality components not only enhance operational efficiency but also reduce downtime and maintenance costs. With rigorous quality control protocols in place, manufacturers can ensure that each part meets precise specifications, contributing to a reliable and smooth-running sewing machine. By collaborating closely with design teams, suppliers can offer innovative solutions that simplify assembly processes and improve overall product functionality. Utilizing advanced materials and state-of-the-art technology during the stamping process allows companies to create components that are not only durable but also lightweight, catering to the diverse requirements of global customers. This commitment to excellence ensures that clients receive products that support their production goals and elevate their brand reputation. Moreover, streamlined logistics from conceptualization to delivery ensures that procurement cycles are efficient and responsive. Timely delivery allows manufacturers to stay ahead in a competitive market, ensuring that they can meet customer demands without interruption. This seamless integration of quality assurance, innovative design, and reliable logistics ultimately empowers global buyers to secure the best sewing machine stamping parts, driving their success in the ever-evolving textile industry.

Sewing Machine Stamping Parts Guarantees Peak Performance From Concept to Delivery

| Parameter | Value |

|---|---|

| Material Type | Stainless Steel |

| Thickness | 1.2 mm |

| Production Method | Stamping & Machining |

| Finish Type | Electro-polished |

| Lead Time | 2-4 weeks |

| Application | Sewing Machines |

| Quality Assurance | ISO 9001 Certified |

| Testing Methods | Tensile Testing, Microscopy |

Related Products