100% Original Factory Stainless Steel Thread Forming Big Aluminum Copper Metal Deep Drawing Part

Our goal is usually to consolidate and improve the high quality and service of existing solutions, meanwhile continuously create new items to meet unique customers’ requires for 100% Original Factory Stainless Steel Thread Forming Big Aluminum Copper Metal Deep Drawing Part, We’re prepared to present you with the most effective ideas over the designs of the orders in a qualified way for those who need. While in the meantime, we continue to keep on producing new technologies and building new designs so as to help make you ahead from the line of this small business.

Our goal is usually to consolidate and improve the high quality and service of existing solutions, meanwhile continuously create new items to meet unique customers’ requires for China Deep Draw Sheet Metal Brass Components, Deep Drawing Press, The credibility is the priority, and the service is the vitality. We promise we now have the ability to provide excellent quality and reasonable price products for customers. With us, your safety is guaranteed.

Description

| Product Type | customized product | |||||||||||

| One-Stop Service | Mold development and design-submit samples-batch production-inspection-surface treatment-packaging-delivery. | |||||||||||

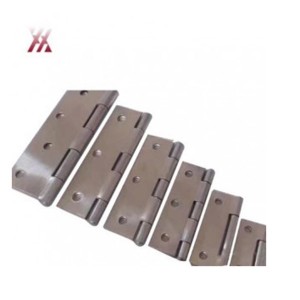

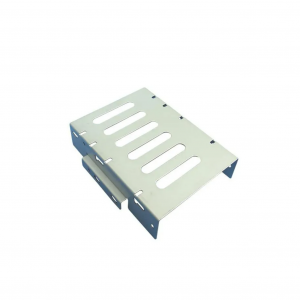

| Process | stamping,bending,deep drawing,sheet metal fabrication,welding,laser cutting etc. | |||||||||||

| Materials | carbon steel,stainless steel,aluminum,copper,galvanized steel etc. | |||||||||||

| Dimensions | according to customer’s drawings or samples. | |||||||||||

| Finish | Spray painting, electroplating, hot-dip galvanizing, powder coating, electrophoresis, anodizing, blackening, etc. | |||||||||||

| Application Area | Auto parts, agricultural machinery parts, engineering machinery parts, construction engineering parts, garden accessories, environmentally friendly machinery parts, ship parts, aviation parts, pipe fittings, hardware tool parts, toy parts, electronic parts, etc. | |||||||||||

Quality Warranty

1. All product manufacturing and inspection have quality records and inspection data.

2. All prepared parts undergo strict testing before being exported to our customers.

3. If any of these parts are damaged under normal working conditions, we promise to replace them one by one for free.

That’s why we’re confident any part we offer will do the job and come with a lifetime warranty against defects.

Quality management

Shipment Picture

Production Process

01. Mold design

02. Mould Processing

03. Wire cutting processing

04. Mold heat treatment

05. Mold assembly

06. Mold debugging

07. Deburring

08. electroplating

09. Product Testing

10. Package

Advantages of metal stamping

Stamping is suitable for mass, complex part production. More specifically, it offers:

- Complex forms, such as contours

- High volumes (from thousands to millions of parts per year)

- Processes such as fineblanking allow for forming of thick metal sheets.

- Low cost-per-piece prices

FAQ

Q1:What is metal stamping?

A1:Metal stamping is a broad category of manufacturing services used to process metal strips or sheets into functional parts.

Q2:Which industries use metal stampings?

A2:Metal stampings are widely used in almost every industry, including automotive, manufacturing, construction, aerospace, electronics, medical, and more.

Q3:What machine produces metal stamping parts?

A3:There are many types of machines that can produce metal stampings. The most common one is the progressive die in a stamping press, other machines include multi-slide and four-slide.

Q4:What are the processes involved in metal stamping?

A4:Some examples of precision stamping manufacturing processes include bending, blanking, stamping, embossing, flanging, high speed, progressive die, punching, and single-stage stamping.

Our goal is usually to consolidate and improve the high quality and service of existing solutions, meanwhile continuously create new items to meet unique customers’ requires for 100% Original Factory Stainless Steel Thread Forming Big Aluminum Copper Metal Deep Drawing Part, We’re prepared to present you with the most effective ideas over the designs of the orders in a qualified way for those who need. While in the meantime, we continue to keep on producing new technologies and building new designs so as to help make you ahead from the line of this small business.

100% Original Factory China Deep Draw Sheet Metal Brass Components and Deep Drawing Press, The credibility is the priority, and the service is the vitality. We promise we now have the ability to provide excellent quality and reasonable price products for customers. With us, your safety is guaranteed.