High reputation Sheet Metal Fabrication Aluminum/Stainless Steel/Carbon Steel Laser Cutting Machining Punching Bending Welding Stamping Parts

We’ve numerous great employees customers excellent at promoting, QC, and working with kinds of troublesome difficulty inside the generation method for High reputation Sheet Metal Fabrication Aluminum/Stainless Steel/Carbon Steel Laser Cutting Machining Punching Bending Welding Stamping Parts, Our service concept is honesty, aggressive, realistic and innovation. With your support, we will grow much better.

We’ve numerous great employees customers excellent at promoting, QC, and working with kinds of troublesome difficulty inside the generation method for China Stamping and Auto Spare Parts, In the increasingly competitive market, With sincere service high quality merchandise and well-deserved reputation, we always supply customers support on items and techniques to achieve long-term cooperation. Living by quality, development by credit is our eternal pursuit, We firmly believe that after your visit we’ll become long-term partners.

Description

| Product Type | customized product | |||||||||||

| One-Stop Service | Mold development and design-submit samples-batch production-inspection-surface treatment-packaging-delivery. | |||||||||||

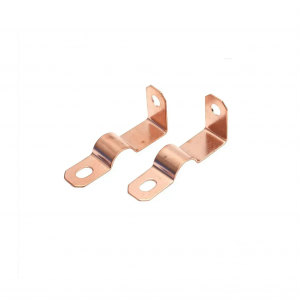

| Process | stamping,bending,deep drawing,sheet metal fabrication,welding,laser cutting etc. | |||||||||||

| Materials | carbon steel,stainless steel,aluminum,copper,galvanized steel etc. | |||||||||||

| Dimensions | according to customer’s drawings or samples. | |||||||||||

| Finish | Spray painting, electroplating, hot-dip galvanizing, powder coating, electrophoresis, anodizing, blackening, etc. | |||||||||||

| Application Area | Auto parts, agricultural machinery parts, engineering machinery parts, construction engineering parts, garden accessories, environmentally friendly machinery parts, ship parts, aviation parts, pipe fittings, hardware tool parts, toy parts, electronic parts, etc. | |||||||||||

Advantags

1. More than 10 years of overseas trade expertise.

2. Provide one-stop service from mold design to product delivery.

3. Fast delivery time, about 30-40 days. In stock within one week.

4. Strict quality management and process control (ISO certified manufacturer and factory).

5. More reasonable prices.

6. Professional, our factory has more than 10 years of history in the field of metal stamping sheet metal.

Quality management

Shipment Picture

Production Process

01. Mold design

02. Mould Processing

03. Wire cutting processing

04. Mold heat treatment

05. Mold assembly

06. Mold debugging

07. Deburring

08. electroplating

09. Product Testing

10. Package

Capabilities

At Xinzhe, we provide a complete in-house tool room to design, engineer, and manufacture all types of metal stamping dies including compound, progressive, draw, and prototype tooling to meet the customer’s requirements.

Above all, Our high-quality, cost-effective metal stamping toolings keep production and operation costs down. Also, we repair and maintain all customers’ dies at no cost to the customer for the whole life of the stamping projects.

- Fast tool modifications to accommodate engineering changes.

- Excellent quality equipments.

- Tool design expertise.

- Well trained and skilled tooling engineers with good knowledge of stamping.

- Advanced Wire EDM cuts your parts accurately and economically.

Industrial Metal Stampings Solutions

Xinzhe Metal Stampings has extensive experience creating custom stamped parts use cold rolled steel solutions for a multitude of industries. Some of the custom industrial metal stamping products include: manufacturing bus bars, flanges, escutcheons, fasteners, battery contacts, electrical housing, clips, washers and a wide variety of other products. We are proud to serivce various industries such as Areospace, Medical, Construction, Automotive, Electrionics, Marine, and Lighiting.

We’ve numerous great employees customers excellent at promoting, QC, and working with kinds of troublesome difficulty inside the generation method for High reputation Sheet Metal Fabrication Aluminum/Stainless Steel/Carbon Steel Laser Cutting Machining Punching Bending Welding Stamping Parts, Our service concept is honesty, aggressive, realistic and innovation. With your support, we will grow much better.

High reputation China Stamping and Auto Spare Parts, In the increasingly competitive market, With sincere service high quality merchandise and well-deserved reputation, we always supply customers support on items and techniques to achieve long-term cooperation. Living by quality, development by credit is our eternal pursuit, We firmly believe that after your visit we’ll become long-term partners.