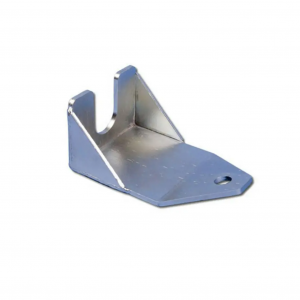

Non-Standard Sheet Metal bending Components, Metal Punching Parts

Description

| Product Type | customized product | |||||||||||

| One-Stop Service | Mold development and design-submit samples-batch production-inspection-surface treatment-packaging-delivery. | |||||||||||

| Process | stamping,bending,deep drawing,sheet metal fabrication,welding,laser cutting etc. | |||||||||||

| Materials | carbon steel,stainless steel,aluminum,copper,galvanized steel etc. | |||||||||||

| Dimensions | according to customer's drawings or samples. | |||||||||||

| Finish | Spray painting, electroplating, hot-dip galvanizing, powder coating, electrophoresis, anodizing, blackening, etc. | |||||||||||

| Application Area | Auto parts, agricultural machinery parts, engineering machinery parts, construction engineering parts, garden accessories, environmentally friendly machinery parts, ship parts, aviation parts, pipe fittings, hardware tool parts, toy parts, electronic parts, etc. | |||||||||||

Why choose us

1.Professional metal stamping parts and sheet metal fabrication for over 10 years.

2.We pay more attention to high standard in production.

3.Excellent service at 24/7.

4.Fast delivery time within one month.

5.Strong technology team back up and support R&D development.

6.Offer OEM cooperation.

7.Good feedback and rare complains among our customers.

8.All products are in good durability and good mechanical property.

9.reasonable and competitive price.

Quality management

Vickers hardness instrument.

Profile measuring instrument.

Spectrograph instrument.

Three coordinate instrument.

Shipment Picture

Production Process

01. Mold design

02. Mould Processing

03. Wire cutting processing

04. Mold heat treatment

05. Mold assembly

06. Mold debugging

07. Deburring

08. electroplating

09. Product Testing

10. Package

The Stamping Process

Metal stamping is a manufacturing process in which coils or flat sheets of material are formed into specific shapes. Stamping encompasses multiple forming techniques such as blanking, punching, embossing, and progressive die stamping, to mention just a few. Parts use either a combination of these techniques or independently, depending on the piece’s complexity. In the process, blank coils or sheets get fed into a stamping press which uses tools and dies to form features and surfaces in the metal. Metal stamping is an excellent way to mass-produce various complex parts, from car door panels and gears to small electrical components used in phones and computers. Stamping processes are highly-adopted in automotive, industrial, lighting, medical, and other industries.

Stamping basics

Placing flat metal in coil or blank form into a stamping machine is the process of stamping, also known as pressing. Metal is shaped into the required shape in a press by tool and die surfaces. Metal can be shaped via punching, blanking, bending, stamping, embossing, and flanging, among other stamping processes.

Stamping experts need to use CAD/CAM engineering to design the mold before the material can be manufactured. To provide adequate clearance for every punch and bend and to achieve the best possible part quality, these designs have to be as exact as possible. Hundreds of parts can be found in a single tool 3D model, making the design process time-consuming and complex in many cases.

After a tool's design is decided upon, producers can finish producing it by using a range of machining, grinding, wire-cutting, and other manufacturing services.