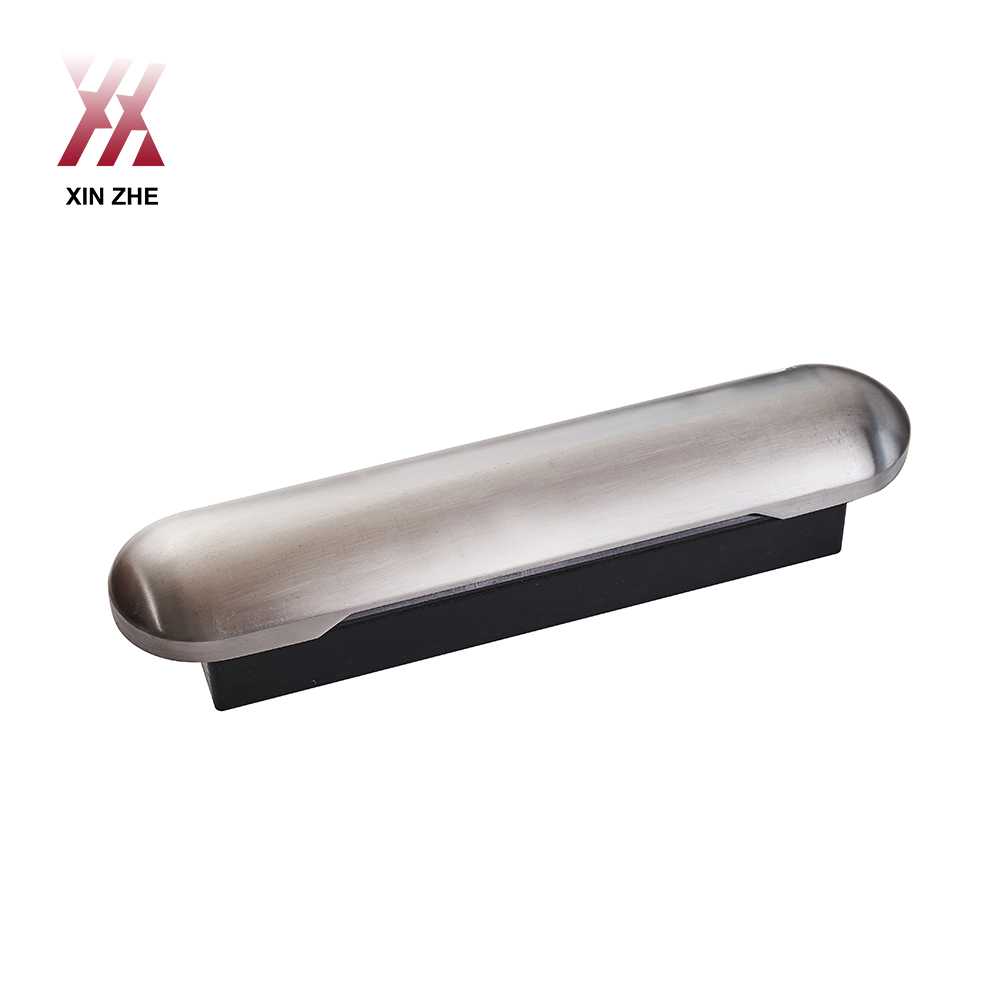

ODM Die Heavy Stamping Factory – Custom Iron Plate Bending Parts – Xinzhe

ODM Die Heavy Stamping Factory – Custom Iron Plate Bending Parts – Xinzhe Detail:

Description

Description

welding process

1. Electrode arc welding:

Electrode arc welding is an arc welding method that uses manual manipulation of electrodes for welding. Therefore, the quality of the weld depends on the welder’s operating technology, which requires the welder to master higher operating skills.( welding sheet metal/ welding thin metal/ tig welding sheet metal)

2. Submerged arc welding (automatic welding):

Submerged arc welding (including submerged arc surfacing and electroslag surfacing, etc.) is a welding method in which the arc burns under the flux layer. Its inherent advantages such as stable welding quality, high welding productivity, no arc light and little smoke make it the main welding method in the manufacture of important steel structures such as pressure vessels, pipe sections, and box beams.( welding thin sheet metal/ best welder for sheet metal)

3. Carbon dioxide gas shielded welding (automatic or semi-automatic welding):

Carbon dioxide gas shielded welding is a kind of welding method, which uses carbon dioxide gas as a shielding gas for welding. In terms of application, it is easy to operate and is suitable for automatic welding and all-round welding. There should be no wind during welding, suitable for indoor work.( tig welding thin metal/ best welder for thin metal/ weld sheet)

Soldering precautions:

1. The length of the arc(bend steel supply)

The length of the arc is related to the type of electrode coating and the thickness of the coating. However, short arcs should be used as much as possible, especially low-hydrogen electrodes. The arc length may cause porosity. The short arc can prevent O2, N2 and other harmful gases in the atmosphere from invading the weld metal, forming undesirable impurities such as oxides and affecting the quality of the weld.( welding aluminum sheet metal/ metal bending)

2. Welding speed(bend iron)

The appropriate welding speed depends on the corresponding changes in conditions such as electrode diameter, coating type, welding current, heat capacity of the object to be welded, and the beginning of the structure, and cannot be stipulated in standards. Maintain a suitable welding speed, and the slag can cover the molten pool well. Make the various impurities and gases in the molten pool have sufficient time to float out, and avoid the formation of slag inclusions and pores in the weld. If the speed of moving the rod is too fast during welding, the shrinkage stress will increase when the welding part cools down, causing cracks in the weld.( sheet metal bender/ sheet metal folder/ steel bending)

Key points for welding wire selection(laser cutting and bending services near me)

The selection of welding wire should be based on the type of steel to be welded, the quality requirements of the welded parts, welding construction conditions (plate thickness, groove shape, welding position, welding conditions, post-weld heat treatment and welding operation wait), cost and other comprehensive considerations.( bending stainless steel/ bending aluminum sheet/ pressbrake)

Product detail pictures:

Related Product Guide:

Now we have superior devices. Our solutions are exported to your USA, the UK and so on, enjoying a superb name between customers for ODM Die Heavy Stamping Factory – Custom Iron Plate Bending Parts – Xinzhe , The product will supply to all over the world, such as: Switzerland, Morocco, Lebanon, We pay high attention to customer service, and cherish every customer. We have maintained a strong reputation in the industry for many years. We are honest and work on building a long-term relationship with our customers.

The factory technical staff gave us a lot of good advice in the cooperation process, this is very good, we are very grateful.