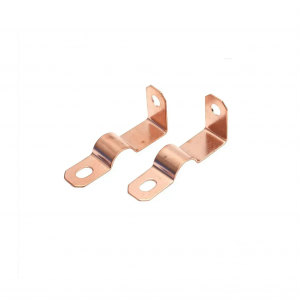

Customized Construction Galvanized Sheet Metal Stamping Clamp Parts

Description

| Product Type | customized product | |||||||||||

| One-Stop Service | Mold development and design-submit samples-batch production-inspection-surface treatment-packaging-delivery. | |||||||||||

| Process | stamping,bending,deep drawing,sheet metal fabrication,welding,laser cutting etc. | |||||||||||

| Materials | carbon steel,stainless steel,aluminum,copper,galvanized steel etc. | |||||||||||

| Dimensions | according to customer's drawings or samples. | |||||||||||

| Finish | Spray painting, electroplating, hot-dip galvanizing, powder coating, electrophoresis, anodizing, blackening, etc. | |||||||||||

| Application Area | Auto parts, agricultural machinery parts, engineering machinery parts, construction engineering parts, garden accessories, environmentally friendly machinery parts, ship parts, aviation parts, pipe fittings, hardware tool parts, toy parts, electronic parts, etc. | |||||||||||

Precision Metal Forming

Xinzhe Metal Stampings is proud of its capacity to create even the most intricate shapes with dies and tools made in-house.

In the past ten years, we have developed tools to make over 8,000 distinct pieces, including several difficult shapes in addition to some easy ones. Xinzhe Metal Stampings frequently accepts jobs that others have declined because they are too challenging or "impossible" to complete. We provide a variety of secondary services to add to your sheet metal fabrication project in addition to working with a wide range of materials.

One of our more recent additions is a Komatsu Servo Punch Press that is state of the art for precision metal forming operations. This press allows us greater flexibility in relation to the number of operations required to achieve extensive metal forming.

Saving you money by providing innovative, cost-effective precision metal forming solutions is our specialty. It’s no surprise that customers have trusted Xinzhe Metal Stampings for their metal forming needs.

Quality management

Vickers hardness instrument.

Profile measuring instrument.

Spectrograph instrument.

Three coordinate instrument.

Shipment Picture

Production Process

01. Mold design

02. Mould Processing

03. Wire cutting processing

04. Mold heat treatment

05. Mold assembly

06. Mold debugging

07. Deburring

08. electroplating

09. Product Testing

10. Package

Company Profile

Ningbo Xinzhe Metal Products Co., Ltd., as a stamping sheet metal supplier in China, specializes in the production of auto parts, agricultural machinery parts, engineering machinery parts, construction engineering parts, hardware accessories, environmentally friendly machinery parts, ship parts, aviation parts, pipe fittings, hardware tools, Toy accessories, electronic accessories, etc.

Through active communication, we can better understand the target market and provide helpful suggestions to help increase our customers' market share, which is beneficial to both parties. In order to win the trust of our customers, we are committed to providing excellent service and high-quality parts. Build long-term relationships with existing clients and seek out future clients in non-partner countries to facilitate collaboration.

WHY CHOOSE US

1.Professional metal stamping parts and sheet metal fabrication for over 10 years.

2.We pay more attention to high standard in production.

3.Excellent service at 24/7.

4.Fast delivery time within one month.

5.Strong technology team back up and support R&D development.

6.Offer OEM cooperation.

7.Good feedback and rare complains among our customers.

8.All products are in good durability and good mechanical property.

9.reasonable and competitive price.