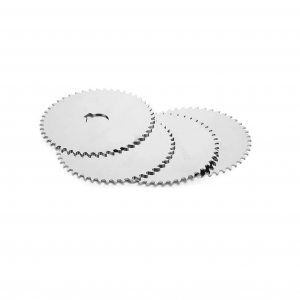

Hot sale Factory Professional Custom CNC Aluminum Stainless Components

We’ve got our personal profits workforce, design and style team, technical group, QC crew and package workforce. We have now strict good quality handle procedures for each process. Also, all of our workers are experienced in printing subject for Hot sale Factory Professional Custom CNC Aluminum Stainless Components, We intention at Ongoing system innovation, management innovation, elite innovation and market place innovation, give full play into the overall advantages, and frequently strengthen services excellent.

We’ve got our personal profits workforce, design and style team, technical group, QC crew and package workforce. We have now strict good quality handle procedures for each process. Also, all of our workers are experienced in printing subject for China CNC Machining Parts and CNC Precision, We can give our clients absolute advantages in product quality and cost control, and we have full range of molds from up to one hundred of factories. As product updating fast, we succeed in developing many high quality products for our clients and get high reputation.

Description

| Product Type | customized product | |||||||||||

| One-Stop Service | Mold development and design-submit samples-batch production-inspection-surface treatment-packaging-delivery. | |||||||||||

| Process | stamping,bending,deep drawing,sheet metal fabrication,welding,laser cutting etc. | |||||||||||

| Materials | carbon steel,stainless steel,aluminum,copper,galvanized steel etc. | |||||||||||

| Dimensions | according to customer’s drawings or samples. | |||||||||||

| Finish | Spray painting, electroplating, hot-dip galvanizing, powder coating, electrophoresis, anodizing, blackening, etc. | |||||||||||

| Application Area | Auto parts, agricultural machinery parts, engineering machinery parts, construction engineering parts, garden accessories, environmentally friendly machinery parts, ship parts, aviation parts, pipe fittings, hardware tool parts, toy parts, electronic parts, etc. | |||||||||||

Metal stamping industry

We provide metal stamping services for a variety of different industries and applications. Our metal stamping industries include, but are not limited to: automotive, aerospace and medical.

Automotive Metal Stamping – Metal stamping is used to create hundreds of different automotive parts, from chassis to door panels to seat belt buckles.

Aerospace Metal Stamping – Metal stamping is a key process in the aerospace industry and is used to create a variety of different components for aerospace projects.

Medical Metal Stamping – Precision metal stamping can be used to manufacture parts and components with the quality and tolerances required in the medical field.

Quality management

Shipment Picture

Production Process

01. Mold design

02. Mould Processing

03. Wire cutting processing

04. Mold heat treatment

05. Mold assembly

06. Mold debugging

07. Deburring

08. electroplating

09. Product Testing

10. Package

The Stamping Process

Metal stamping is a manufacturing process in which coils or flat sheets of material are formed into specific shapes. Stamping encompasses multiple forming techniques such as blanking, punching, embossing, and progressive die stamping, to mention just a few. Parts use either a combination of these techniques or independently, depending on the piece’s complexity. In the process, blank coils or sheets get fed into a stamping press which uses tools and dies to form features and surfaces in the metal. Metal stamping is an excellent way to mass-produce various complex parts, from car door panels and gears to small electrical components used in phones and computers. Stamping processes are highly-adopted in automotive, industrial, lighting, medical, and other industries.

Metal Stamping Production Volumes

Short-run stamping is a low-volume production run with limited tool revisions. With short runs, overall costs will be less since you won’t need to change processes or equipment as much. Very short runs will have no changing factors, enabling the lowest price. These production capabilities are best for parts requiring less flexibility, low volume, or entering a new market.

Long Run Stamping

Long-run stamping is a more involved production run in which all factors are variable, allowing for greater flexibility over time as the production line is tuned and optimized for scale. Long-run stamping will incur more costs as each process, material, or machine part may be changed and tested. However, these changes provide consistent quality, low per-unit costs, and incredible throughput of up to hundreds of parts a minute.

We’ve got our personal profits workforce, design and style team, technical group, QC crew and package workforce. We have now strict good quality handle procedures for each process. Also, all of our workers are experienced in printing subject for Hot sale Factory Professional Custom CNC Aluminum Stainless Components, We intention at Ongoing system innovation, management innovation, elite innovation and market place innovation, give full play into the overall advantages, and frequently strengthen services excellent.

Hot sale Factory China CNC Machining Parts and CNC Precision, We can give our clients absolute advantages in product quality and cost control, and we have full range of molds from up to one hundred of factories. As product updating fast, we succeed in developing many high quality products for our clients and get high reputation.