PriceList for Custom Made Sheet Metal Stamping for Electrical Appliance

Our well-equipped facilities and exceptional top quality handle throughout all stages of production enables us to guarantee total client fulfillment for PriceList for Custom Made Sheet Metal Stamping for Electrical Appliance, We welcome buyers everywhere in the word to get in touch with us for future business enterprise interactions. Our merchandise are the most effective. Once Selected, Ideal Forever!

Our well-equipped facilities and exceptional top quality handle throughout all stages of production enables us to guarantee total client fulfillment for China Stamping and Stainless Steel Sheet Metal Products, To win customers’ confidence, Best Source has set up a strong sales and after-sales team to provide the best product and service. Best Source abides by the idea of “Grow with customer” and philosophy of “Customer-oriented” to achieve cooperation of mutual trust and benefit. Best Source will always stand ready to cooperate with you. Let’s grow together!

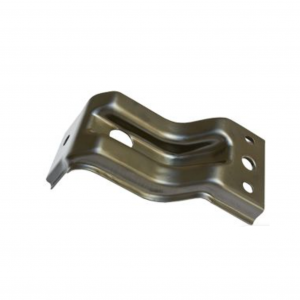

Description

| Product Type | customized product | |||||||||||

| One-Stop Service | Mold development and design-submit samples-batch production-inspection-surface treatment-packaging-delivery. | |||||||||||

| Process | stamping,bending,deep drawing,sheet metal fabrication,welding,laser cutting etc. | |||||||||||

| Materials | carbon steel,stainless steel,aluminum,copper,galvanized steel etc. | |||||||||||

| Dimensions | according to customer’s drawings or samples. | |||||||||||

| Finish | Spray painting, electroplating, hot-dip galvanizing, powder coating, electrophoresis, anodizing, blackening, etc. | |||||||||||

| Application Area | Auto parts, agricultural machinery parts, engineering machinery parts, construction engineering parts, garden accessories, environmentally friendly machinery parts, ship parts, aviation parts, pipe fittings, hardware tool parts, toy parts, electronic parts, etc. | |||||||||||

Advantags

1. More than 10 years of overseas trade expertise.

2. Provide one-stop service from mold design to product delivery.

3. Fast delivery time, about 30-40 days. In stock within one week.

4. Strict quality management and process control (ISO certified manufacturer and factory).

5. More reasonable prices.

6. Professional, our factory has more than 10 years of history in the field of metal stamping sheet metal.

Quality management

Shipment Picture

Production Process

01. Mold design

02. Mould Processing

03. Wire cutting processing

04. Mold heat treatment

05. Mold assembly

06. Mold debugging

07. Deburring

08. electroplating

09. Product Testing

10. Package

Tight tolerances

Whether you are in the aerospace, automotive, telecommunications or electronics industry, our precision metal stamping services can deliver the part shapes you require. Our suppliers work hard to meet your tolerance requirements by iterating tool and mold designs to fine-tune output to meet your needs. However, the tighter the tolerances, the more difficult and costly it is. Precision metal stampings with tight tolerances can be brackets, clips, inserts, connectors, accessories and other parts in consumer appliances, power grids, aircraft and automobiles. They are also used to make implants, surgical instruments, temperature probes and other medical device parts such as housings and pump components.

Regular checks after each successive run to ensure the output is still within specification is typical for all stampings. Quality and consistency are part of a comprehensive production maintenance program that monitors stamping tool wear. Measurements using inspection jigs are standard measurements on long-running stamping lines.

Our quality policy

Focusing on the continuous improvement of the production process to deliver our metal stamping parts to the customers with the best quality and excellent customer service.

We are practicing the international quality management system from head to toe conforming to customers’ specific requirements.

Our quality goal

1. Decrease tools set-up and change-over-time by 75% or higher compared to the average time in stamping field.

2. keep the reject rate under 1% and replace every single reject with a good one.

3. Improve the On-Time delivery rate to 98% or higher.

Our well-equipped facilities and exceptional top quality handle throughout all stages of production enables us to guarantee total client fulfillment for PriceList for Custom Made Sheet Metal Stamping for Electrical Appliance, We welcome buyers everywhere in the word to get in touch with us for future business enterprise interactions. Our merchandise are the most effective. Once Selected, Ideal Forever!

PriceList for China Stamping and Stainless Steel Sheet Metal Products, To win customers’ confidence, Best Source has set up a strong sales and after-sales team to provide the best product and service. Best Source abides by the idea of “Grow with customer” and philosophy of “Customer-oriented” to achieve cooperation of mutual trust and benefit. Best Source will always stand ready to cooperate with you. Let’s grow together!