Top Grade Graphite Stainless Steel Composite Gasket with High Strength

We have a professional, efficiency team to provide quality service for our customer. We always follow the tenet of customer-oriented, details-focused for Top Grade Graphite Stainless Steel Composite Gasket with High Strength, Objects won certifications together with the regional and international primary authorities. For far a lot more detailed information, make sure you make contact with us!

We have a professional, efficiency team to provide quality service for our customer. We always follow the tenet of customer-oriented, details-focused for China Composite Gasket, Plastic Gasket, we rely on own advantages to build a mutual-benefit commerce mechanism with our cooperative partners. As a result, now we have gained a global sales network reaching the Middle East, Turkey, Malaysia and Vietnamese.

Description

| ModelNO | XZ0015 |

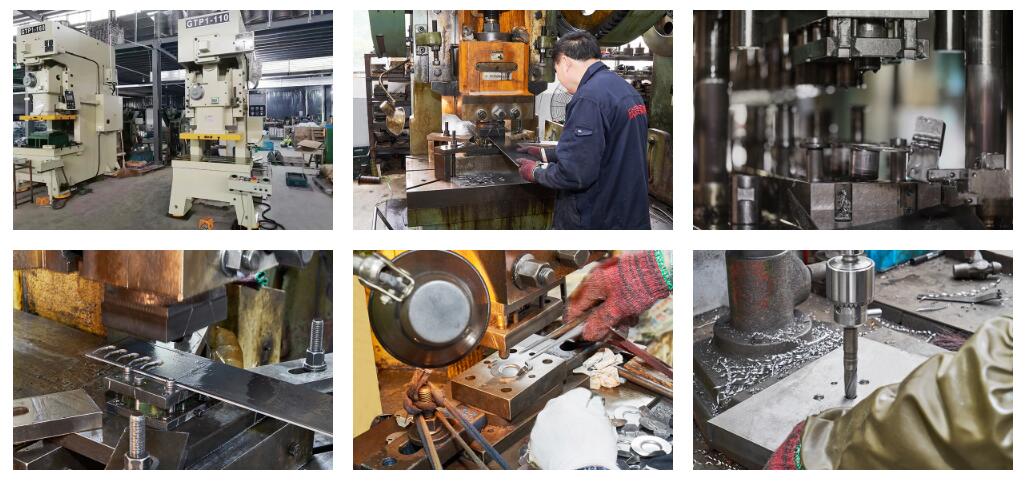

| Process | blanking welding Process |

| Industry | Metal Stamping Parts |

| Tolerances | 0.1mm |

| Customized | Customized |

| Name | High-precision custom metal gaskets |

| Size | Customized |

| Work | Stamping |

| Surface Finish | electroplate |

| Delivery Time | 30 Days |

| Company Location | Ningbo |

| Transport Package | PP Bag/Carton or According Customers′ Requirement |

| Certificate ISO9001 | 2015 |

| Origin | Ningbo Production Capacity |

| Metal Stamping Process | 50000PCS/Month |

FAQ

What are the definitions and uses of metal gaskets?

Metal gaskets are refined from high-precision, high-hardness sheet materials, usually used in the adjustment and measurement of precision molds or precision hardware, or as pads, called precision gaskets, sometimes also called mold gaskets or Precision gaps.( metal gasket ring)

Description

The use of metal gaskets: used in electronic instruments, mold manufacturing, precision machinery, hardware parts, mechanical parts, stamping parts, hardware manufacturing. This product can be used to solve the problem of machine maintenance for mold maintenance, mold measurement gap and shaking, swaying and instability due to mechanical aging. The sealing effect in flange connection is also a great use of metal gaskets.( metallic seal)

Types of gaskets: There are many types of gaskets, which can be roughly divided into three categories according to their materials and structures:

1. Non-metallic gaskets, including rubber. Asbestos rubber sheet, flexible graphite, the cross-sectional shape is rectangular; (corrugated metal gasket)

2. Metal composite gaskets, there are various metal wrapped gaskets, metal winding gaskets;( spiral wound metallic gasket)

3. Metal gaskets, including metal flat gaskets, wave gaskets, ring gaskets, tooth gaskets Type pads, hollow O-rings, C-type pads, triangular pads, etc.( steel door seal)

Gaskets generally play a sealing role: gaskets made of relatively soft materials are added between two planes that need to be sealed, so that it is easy to meet the sealing requirements, such as in flanged pipes, between two flanges The gasket, the gasket between the engine block and the cylinder head, acts as a seal. However, there are usually connecting parts used to increase the area of the fastening force, that is, to disperse the pressure of the nut, to protect the flat washer of the connection surface, or to lock the screw nut, the spring washer for anti-loosening, and the butterfly type Washers are called “flat washers” and “spring washers”.( metal detectable gaskets)

Installation Requirements

1. The sealing surface of the gasket and the flange should be cleaned, and there should be no scratches, spots and other defects that affect the sealing performance of the connection.( steel gasket)

2. The outer diameter of the sealing gasket should be smaller than that of the flange sealing surface, and the inner diameter of the sealing gasket should be slightly larger than the inner diameter of the pipe. The difference between the two inner diameters is generally twice the thickness of the sealing gasket to ensure that the sealing gasket will The inner edge will not protrude into the container or pipe, so as not to hinder the flow of fluid in the container or pipe.( rubber coated metal gaskets)

3. The pretightening force of the sealing gasket should not exceed the design specification, so as to avoid the excessive compression of the sealing gasket and the loss of resilience.( garlock metallic gaskets)

4. It is best to use a torque wrench to tighten the gasket. For large bolts and high-strength bolts, it is best to use hydraulic tensioners. The tightening torque should be obtained through calculation according to the compression of the given sealing gasket, and the oil pressure of the hydraulic tightener should also be determined through calculation.( wire mesh gasket)

5. When installing the sealing gasket, the nuts should be tightened in sequence. But it should not be screwed once to reach the design value. Generally, it should be cycled at least 2 to 3 times so that the stress distribution of the sealing gasket is even.( camprofile gasket)

6. For pressure vessels and pipelines with flammable and explosive media, safety tools should be used when replacing sealing gaskets, so as to avoid sparks caused by tools colliding with flanges or bolts, resulting in fire or explosion accidents.( aluminum gasket)

7. If the pipeline leaks, it must be depressurized before replacing or adjusting the installation of the sealing gasket. Operation under pressure is strictly prohibited.( metal detectable tri clamp gaskets)

We have a professional, efficiency team to provide quality service for our customer. We always follow the tenet of customer-oriented, details-focused for Top Grade Graphite Stainless Steel Composite Gasket with High Strength, Objects won certifications together with the regional and international primary authorities. For far a lot more detailed information, make sure you make contact with us!

Top Grade China Composite Gasket and Plastic Gasket, we rely on own advantages to build a mutual-benefit commerce mechanism with our cooperative partners. As a result, now we have gained a global sales network reaching the Middle East, Turkey, Malaysia and Vietnamese.