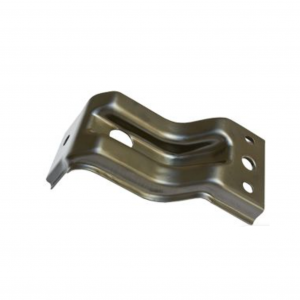

Customized sheet metal bending and stamping stainless steel bracket

Description

| Product Type | customized product | |||||||||||

| One-Stop Service | Mold development and design-submit samples-batch production-inspection-surface treatment-packaging-delivery. | |||||||||||

| Process | stamping,bending,deep drawing,sheet metal fabrication,welding,laser cutting etc. | |||||||||||

| Materials | carbon steel,stainless steel,aluminum,copper,galvanized steel etc. | |||||||||||

| Dimensions | according to customer's drawings or samples. | |||||||||||

| Finish | Spray painting, electroplating, hot-dip galvanizing, powder coating, electrophoresis, anodizing, blackening, etc. | |||||||||||

| Application Area | Auto parts, agricultural machinery parts, engineering machinery parts, construction engineering parts, garden accessories, environmentally friendly machinery parts, ship parts, aviation parts, pipe fittings, hardware tool parts, toy parts, electronic parts, etc. | |||||||||||

Advantags

1. Over ten years of experience in international trade.

2. Offer a one-stop shop for everything from product delivery to mold design.

3. Quick delivery, taking between 30 and 40 days. within a week's supply.

4. Strict process control and quality management (manufacturer and factory with ISO certification).

5. More affordable costs.

6. Skilled: With over a decade of experience, our plant has been stamping sheet metal.

Quality management

Vickers hardness instrument.

Profile measuring instrument.

Spectrograph instrument.

Three coordinate instrument.

Shipment Picture

Production Process

01. Mold design

02. Mould Processing

03. Wire cutting processing

04. Mold heat treatment

05. Mold assembly

06. Mold debugging

07. Deburring

08. electroplating

09. Product Testing

10. Package

Company Profile

Ningbo Xinzhe Metal Products Co., Ltd., as a stamping sheet metal supplier in China, specializes in the production of auto parts, agricultural machinery parts, engineering machinery parts, construction engineering parts, hardware accessories, environmentally friendly machinery parts, ship parts, aviation parts, pipe fittings, hardware tools, Toy accessories, electronic accessories, etc.

Through active communication, we can better understand the target market and provide helpful suggestions to help increase our customers' market share, which is beneficial to both parties. In order to win the trust of our customers, we are committed to providing excellent service and high-quality parts. Build long-term relationships with existing clients and seek out future clients in non-partner countries to facilitate collaboration.

Sheet metal type

Typical kinds of bent sheet metal components:

1. Box workpieces: Cabinets, chassis, instrument boxes, electrical boxes, and other similar workpieces are the most prevalent kind in sheet metal processing. Flat materials can be bent into different box components using sheet metal bending, and then they can be bolted or welded together to form a whole box.

2. Bracket workpieces: These workpieces, which include light frame brackets and heavy machinery brackets, are typically composed of steel plates in a variety of lengths and diameters. Brackets with varying specifications can be produced using sheet metal bending by adjusting the bending angle and length.

3. Round workpieces: These workpieces primarily consist of spherical and conical elements, among others. Flat semicircular, sector-shaped, and other materials can be bent into circular parts using sheet metal bending technology. By precisely controlling the bending angle, high-precision circular parts production can be accomplished.

4.Bridge workpieces: These workpieces' lengths and bending angles vary based on the kind of use, such as stage light stands, amusement park equipment, etc. Bridge-like workpieces in a variety of sizes can be produced with sheet metal bending technology, and they have the advantages of precise positioning, high processing precision, and simple installation.

5. Other workpiece kinds: There are a variety of workpiece types, including steel structures, roofs, shells, and more, in addition to the typical sheet metal bending workpieces previously mentioned. Professional sheet metal bending longitudinal and transverse processing techniques are needed for various workpiece types.

Get in touch with Xinzhe Metal Stampings right now if you're searching for a precision metal stamping business that can provide beautiful, customized component parts. We would be pleased to talk with you about your project and provide you a free estimate.